To efficiently manage project schedules, it is necessary to clearly define the scope of work, break down each task thoroughly, and accurately determine the sequence and duration of construction activities. A good schedule management plan not only well persuades the Investor but also optimizes costs and resources.

Objectives of construction schedule management plan

A detailed construction schedule management plan includes accurate cost and time estimates for each task, optimizes resource allocation, and ensures the project is completed on time and within the set budget. Additionally, a well-organized schedule with logical tasks and personnel assignments helps ensure labor safety in construction and maintains high-quality standards for the project.

What makes a good construction schedule management plan?

To optimize the budget and effectively manage the factory construction timeline, a good schedule management plan should ensure the following:

- Detail: The plan must be clear and detailed, outlining specific tasks, completion times, and necessary resources for each phase.

- Logical Order: Tasks should be arranged in a logical sequence based on their dependencies and precedence relationships, avoiding conflicts and wasted time.

- Resource Optimization: Ensure efficient use and proper allocation of manpower, materials, and equipment, avoiding waste.

- Always have a plan for quality control and equipment testing.

- Reasonable work schedule, consider weather factors to develop flexible handling plans.

- Appropriate Buffer Time: The project should include buffer time to address unexpected issues that may arise.

Steps for effectively managing schedule of factory construction project

Define the project scope

The first step in planning a project schedule is to fully define the project scope of work. Construction contractors need to clearly specify the scope of work, address any questions related to the scope, quality requirements, material specifications, and establish a timeline, quality evaluation criteria, and acceptance procedures with the investor. This step helps the contractor understand the entire project clearly, allowing for the development of an accurate and appropriate project management plan.

Break down project work items

Breaking down the scope of work involves identifying and detailing the specific tasks that need to be completed. There are various tools for breaking down work, such as mind maps, work breakdown structures (WBS), etc. However, common tools used in construction project management are Microsoft Excel and Microsoft Project. Regardless of the tool used, contractors must ensure that all work packages are listed in each work item and that all necessary tasks for the project are included. Any mistakes or omissions at this stage can seriously impact the planning and execution of the project schedule.

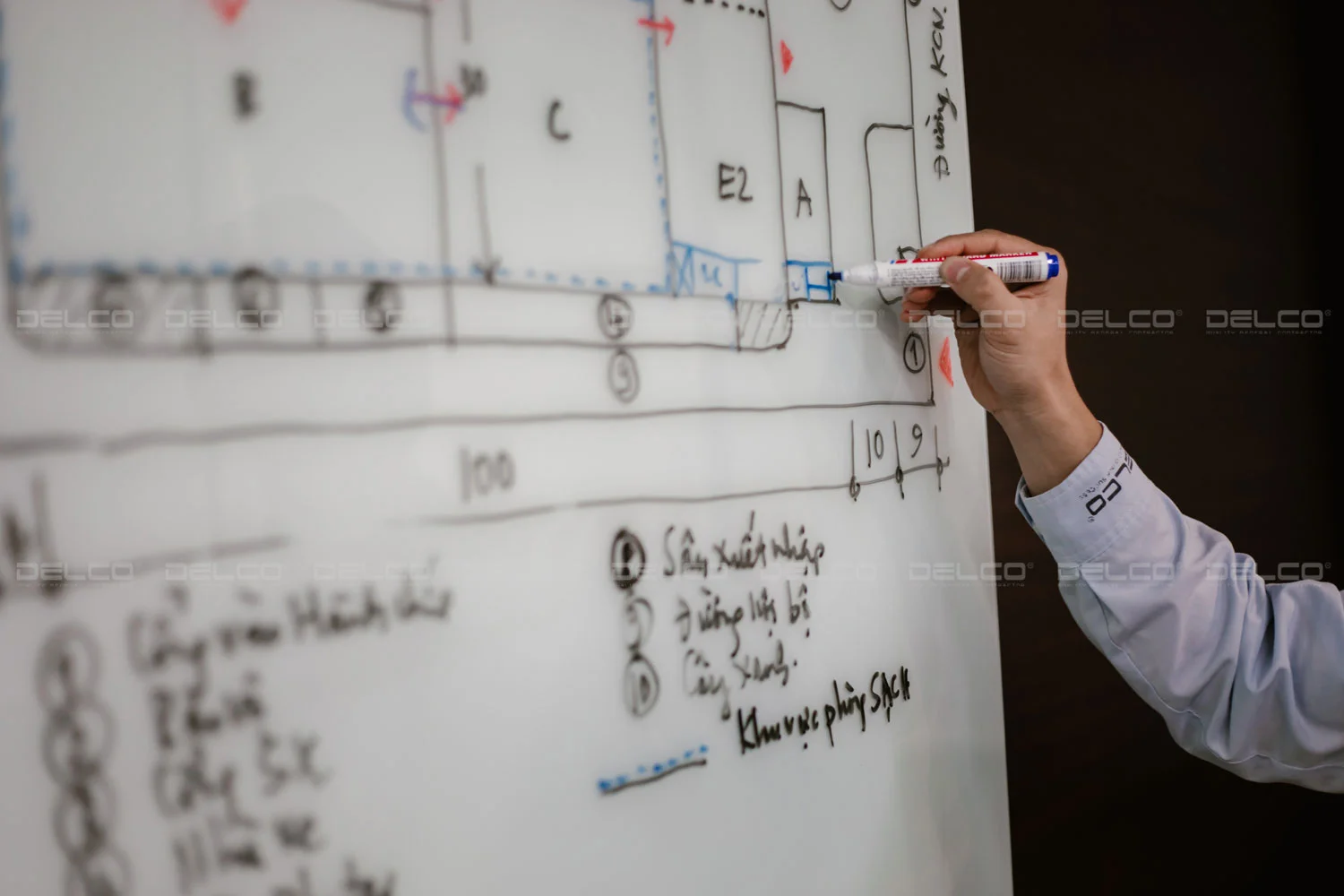

Plan a reasonable factory construction sequence

Some items must be completed sequentially, such as pile driving, machine foundation construction, then building – plastering the wall, the wall must reach the appropriate moisture level before applying primer and paint, etc. Meanwhile, some other items can be constructed in parallel, like partition wall construction, MEP construction, and finishing work. The Precedence Diagramming Method (PDM) is a helpful tool for illustrating the relationships between tasks and detailed work packages, helping contractors plan reasonable construction sequences and manage progress effectively.

Estimate the construction schedule

Accurately estimating the construction timeline is crucial for project schedule management. Overestimating can lead to wasted resources and increased costs, while underestimating can affect the technical time required for each task and reduce construction quality. The bottom-up technique is a common method for estimating construction timelines in industrial projects, providing precise estimates down to each phase and each smallest work package. However, it requires experienced contractors with a deep understanding of the project. Additionally, the project schedule management plan must account for potential risks, such as unfavorable weather, material shortages, or difficulties in mobilizing labor.

Develop a detailed schedule

Based on the construction sequence and estimated timelines for each task, contractors create a detailed schedule. The Gantt chart is a commonly used tool for visually tracking and managing progress, providing a clear overview of each work package’s start and end dates, construction phases, quality inspection and acceptance milestones, etc. This tool helps contractors plan the mobilization of necessary labor and equipment for each task. Techniques like smoothing and leveling can be used in this tool to distribute resources evenly across all phases, preventing overallocation or underallocation, which can negatively impact the project’s timeline and lead to unnecessary costs.

Control project schedule

Controlling and managing the project schedule is an ongoing process from the project’s initial to the handover of the completed factory, requiring the contractor’s carefulness and meticulousness. Contractors need to closely monitor each work item, regularly update the actual progress, manage any arising issues, and always be ready with contingency plans to deal with risks, closely following the progress plan.

See more: The most popular waterproofing methods for factories nowadays