By 2025, factory fit-outs for rental facilities have become a popular and optimal choice for foreign direct investment (FDI) investors. This approach helps reduce investment costs, streamline administrative procedures, and enable rapid production start-up. To ensure flexibility and functionality, investors must carefully evaluate and select appropriate fit-out solutions.

Key considerations for MEP system design in factory fit-outs

For rental factories, the mechanical, electrical, and plumbing (MEP) systems, along with basic technical infrastructure, are typically pre-installed. However, different industries have varying requirements for electricity, water, ventilation, air conditioning, compressed air, and wastewater treatment. Therefore, investors must carefully assess fit-out design solutions and adjust the MEP system to align with their production processes while ensuring compatibility with the overall infrastructure.

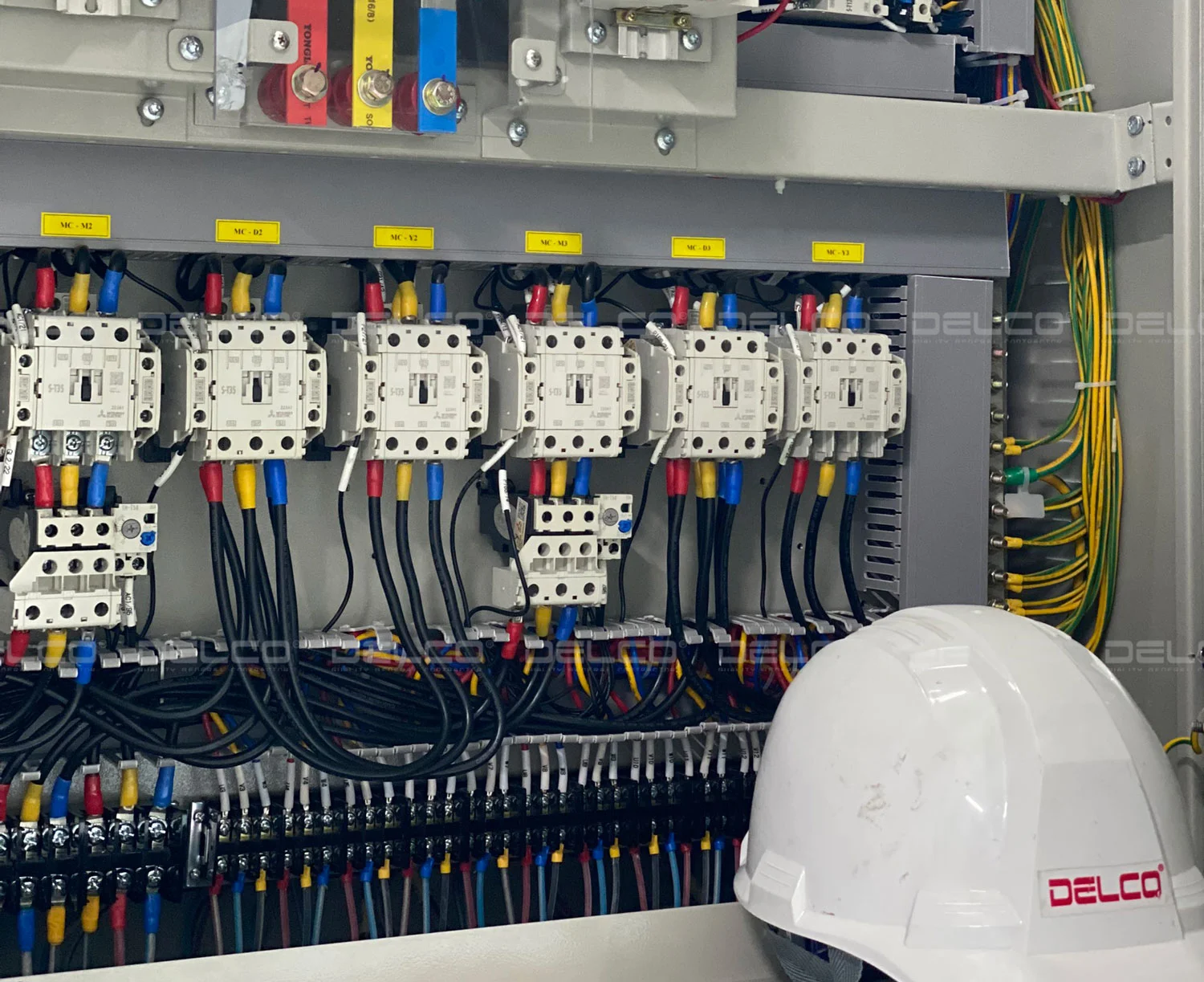

The electrical system must be designed to be compatible with the existing infrastructure while ensuring stable production capacity. Connection methods should be carefully calculated to comply with technical standards, preventing overloads or operational safety risks. The HVAC and water supply and drainage systems should also be upgraded appropriately, especially for industries with stringent requirements such as food processing, pharmaceuticals, and electronics. For the fire protection system, it is essential to check its compatibility with the existing system in relation to the factory’s scale and characteristics, ensuring adequate fire water supply, alarm systems, and firefighting equipment in full compliance with technical regulations.

A flexible and cost-effective factory fit-out solution

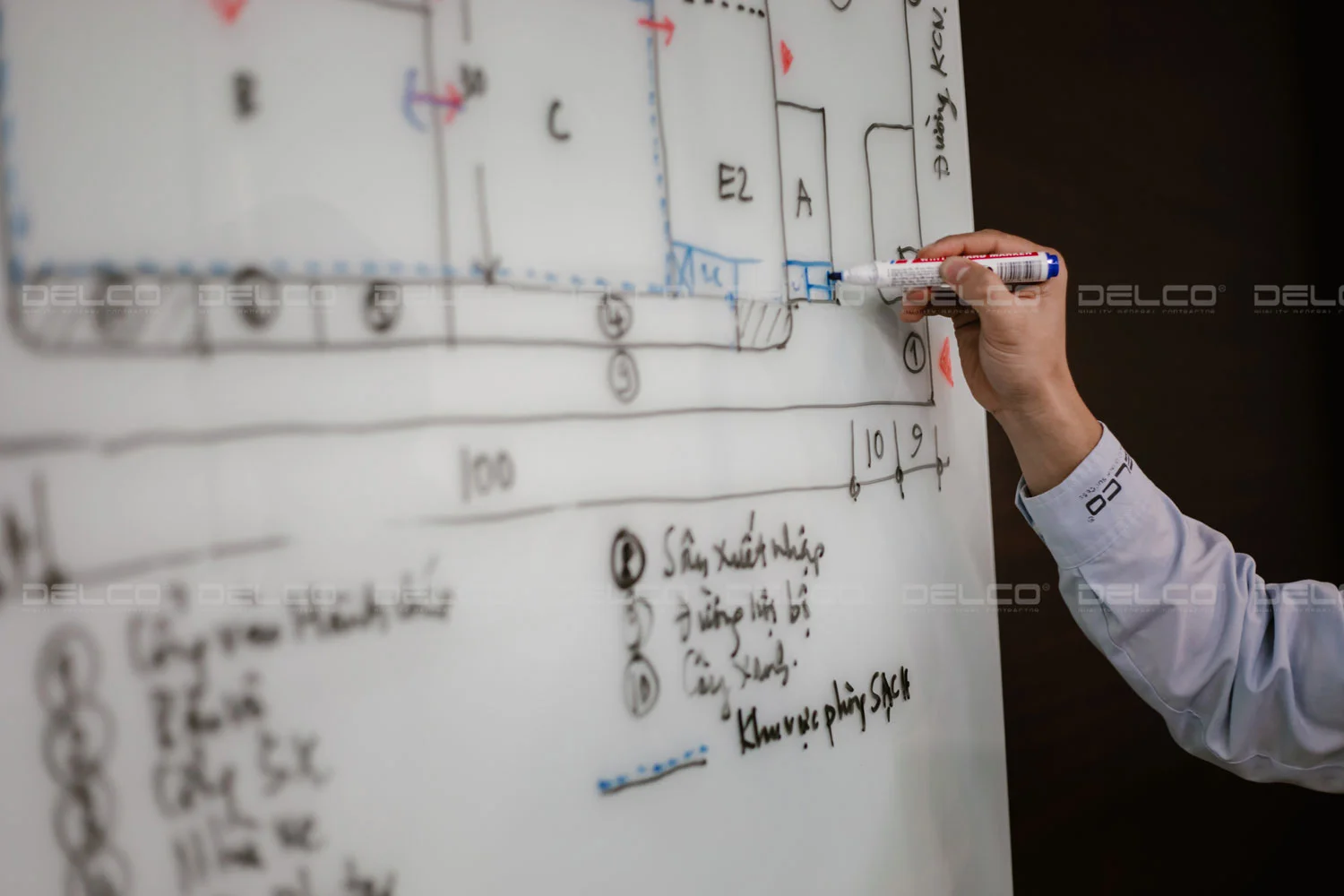

One of the key criteria when selecting a factory fit-out contractor is the ability to implement flexible construction solutions, including the dismantling, upgrading, or renovation of pre-built factories, helping investors minimize fit-out costs as well as reduce expenses related to dismantling and site restoration at the end of the lease. This requires the contractor to develop an intelligent layout plan, making the most of existing infrastructure, utilizing modular structures or overhead cable systems for maximum flexibility.

The technical ceiling solution using modular panel assemblies combined with a suspension system with threaded rods ensures flexibility and cost optimization in the HAEM VINA 3 factory fit-out project.

Scientific functional space planning

Pre-built factories often have limited space and layout constraints. Therefore, fit-out solutions in construction should focus on smart space arrangement, efficient and convenient traffic systems, and maximizing usable area while maintaining production efficiency. Space allocation must be carefully planned to support the production process, ensuring smooth movement of workers, machinery, and materials. Internal traffic systems should be designed to align with the flow of goods, prioritizing forklifts and machinery for optimal operation while minimizing congestion.

See also: Design and planning options for factory traffic management

Essential auxiliary systems in factory fit-outs

When considering factory fit-out solutions, investors must pay special attention to the proper arrangement of auxiliary systems such as waste disposal areas, compressor stations, and air conditioning units. Since many rental factories maximize their construction density, adding these systems can be challenging.

Outdoor installation solutions for machinery systems such as cooling towers and gas treatment systems in the DAINESE factory fit-out project by DELCO as the Design-Build contractor

One effective solution is to install auxiliary systems outdoors while implementing protective measures to ensure operational safety and stability. Additionally, utilizing overhead space by placing some auxiliary equipment on the roof or mezzanine can help optimize ground-level space usage. For waste disposal areas, it is essential to ensure a suitable location with proper ventilation and odor treatment systems to prevent any impact on the production environment.

See also: Key changes in factory fitout in 2025

See also: 6 key factors to consider to build or lease a workshop