Factory fit-out is often imagined as a simple finishing phase after a site is handed over. This perspective leads to many misunderstandings during implementation, as fit-out work in reality is not limited to on-site construction but is closely linked to factory conditions, operational requirements, and related procedures. The article below clarifies several aspects that are often not fully understood in factory fit-out projects in Vietnam.

1. Factory fit-out timelines are heavily affected by legal procedures

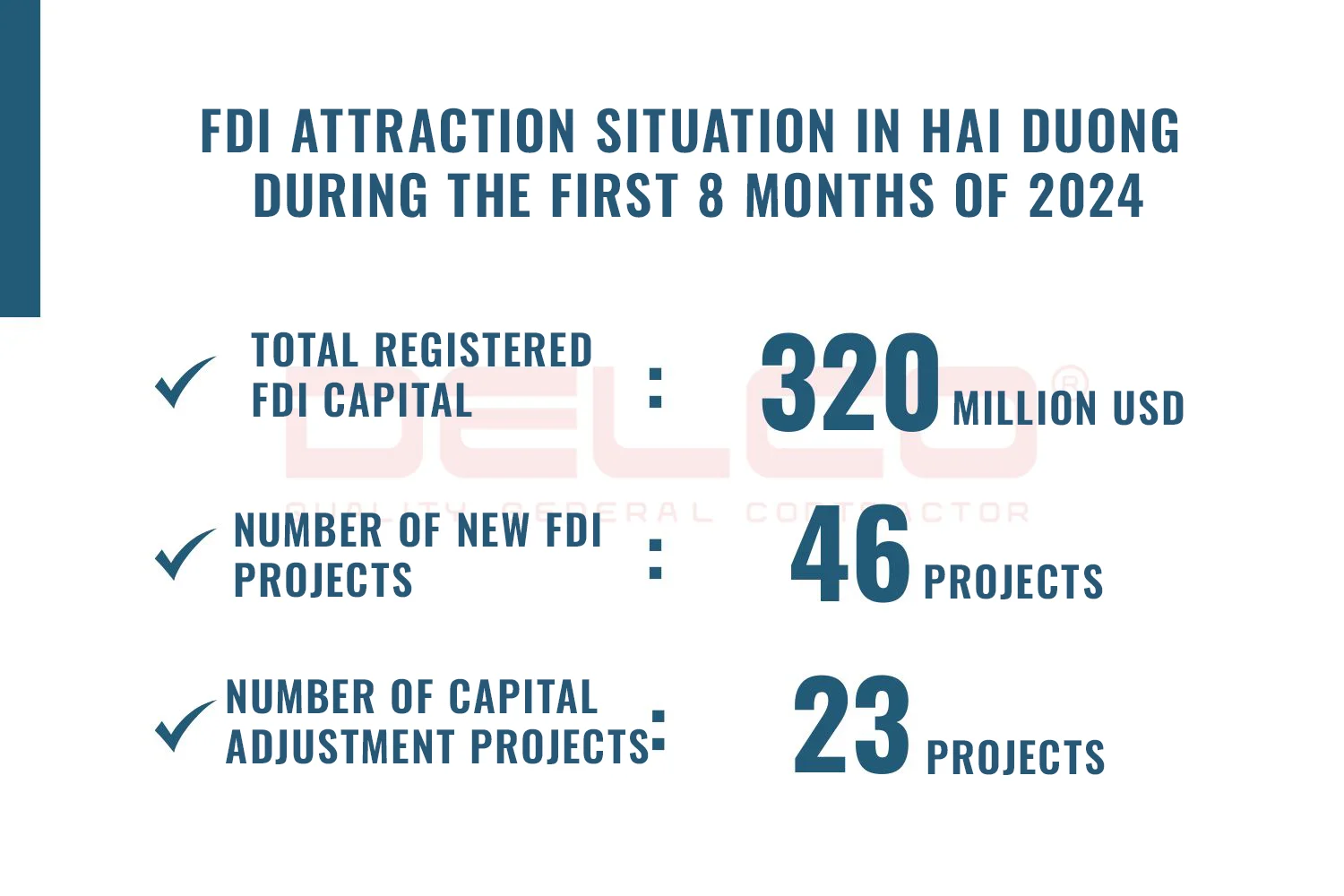

In many projects, fit-out progress is commonly understood and monitored through on-site construction progress. However, in practice, in addition to construction activities, the fit-out process also includes many procedural and administrative milestones. Items such as IRC, ERC, environmental permits, fire prevention and fighting appraisal and acceptance, as well as technical infrastructure connections, are all part of the overall implementation process.

These milestones need to be carried out in parallel with construction and are difficult to fully reflect if progress is viewed only from on-site activities. Therefore, in the context of implementation in Vietnam, considering fit-out progress as a whole that includes both construction and related procedures helps project plans align more closely with actual execution sequences.

2. The investor does not have full decision-making authority over all work scopes, even as the paying party

A common misconception is that once a party acts as the investor and bears the project costs, all decisions in a fit-out project can be made independently. In practice, when implementing an industrial fit-out, the investor typically needs to coordinate with multiple stakeholders related to the leased premises and existing infrastructure, such as the landlord, industrial park management, power utility, and fire safety authorities.

Even for items considered “internal,” adjustments to technical solutions, layouts, or system connections still require approval from the relevant authorities. In many cases, solutions that are technically feasible or operationally optimal may not comply with industrial park standards or current management requirements.

3. Many important items may arise during construction

Another common misunderstanding is the assumption that all decisions in a factory fit-out can be fully finalized during the design stage. In practice, fit-out is rarely a completely “locked-in” process from the outset. In many projects, production line installation takes place in parallel with construction, while certain technical parameters continue to be updated by equipment suppliers or the parent company.

As a result, during implementation, projects often need to allow flexibility to handle technical adjustments as specifications are finalized. This is a structural characteristic of many factory fit-out projects, where design, construction, and production line installation must be continuously coordinated and updated to ensure the final solution aligns with actual operational requirements.

4. Rental factories are designed to general standards

Most rental factories in Vietnam are designed according to general-purpose standards to serve a wide range of tenants. This approach helps optimize leasing potential, but as a result, it may not be compatible with certain specific production lines, especially in specialized industries such as Electronics, Food Processing, Metallurgy, and Heavy Industry.

When implementing fit-out works, the differences between the factory’s general standards and the specific requirements of production lines often become more apparent. Aspects related to floor load capacity, working height, spatial zoning, environmental conditions, or auxiliary technical systems may need to be reviewed and adjusted to suit actual factory operations.

5. The investor’s project organization directly affects timelines

Fit-out timelines depend not only on contractual terms or contractor capacity, but are also significantly influenced by the investor’s own project organization. Internal approval processes, decision-making authority delegation, and the level of coordination among departments directly affect implementation flow.

In many cases, delays are not clearly shown on progress charts but accumulate through waiting periods for approvals, changes in requirements, or internal misalignment. These causes often only become apparent once the project misses its operational handover milestone.

Understanding these factors helps investors approach fit-out timelines more realistically, while also assessing their own level of readiness before entering the implementation phase.

DELCO typically approaches fit-out projects from a holistic perspective, considering the interrelationship between design, construction, and long-term operation, rather than focusing solely on short-term execution speed. Not every project requires a complex model, and not every project is suitable for the same approach. Choosing the right method depends largely on each investor’s readiness and practical objectives.