Industrial cooling systems for factories in Vietnam need to be tailored to the specific needs of each industry, comply with international technical standards such as ASHRAE and CIBSE, and suit the country’s tropical climate. Choosing the right technology—whether water-cooled chillers, air-cooled chillers, NH₃, CO₂, glycol systems, or VRF—not only helps maintain production quality but also optimizes operational costs and lays the foundation for sustainable business growth.

1. The role of cooling systems in factories

Industrial cooling plays a key role in manufacturing operations—especially in sectors like food, pharmaceuticals, electronics, mechanical engineering, and industrial processing. Proper control of temperature, humidity, and air quality helps ensure consistent product quality, stable production processes, and extended equipment lifespan.

In Vietnam’s hot and humid tropical climate, system design must take into account:

- Energy efficiency, following ASHRAE 90.1 standards

- Operational safety (especially with NH₃ or CO₂ systems, in line with TCVN 6104-1 and NFPA standards)

- Compliance with industry-specific standards such as GMP for pharmaceuticals, HACCP/ISO 22000 for food processing, or ESD/cleanroom requirements for electronics

A properly designed system will strike the right balance between initial investment, operating cost, performance, and long-term durability.

2. Popular cooling systems in Vietnam

Depending on the factory’s scale and production characteristics, the following cooling systems are widely used:

- Water-cooled chiller: High efficiency (COP 5.5–6.5), uses a cooling tower, suitable for large-scale factories.

- Air-cooled chiller: Compact, no cooling tower required, ideal for areas with limited water or medium-to-small-sized workshops.

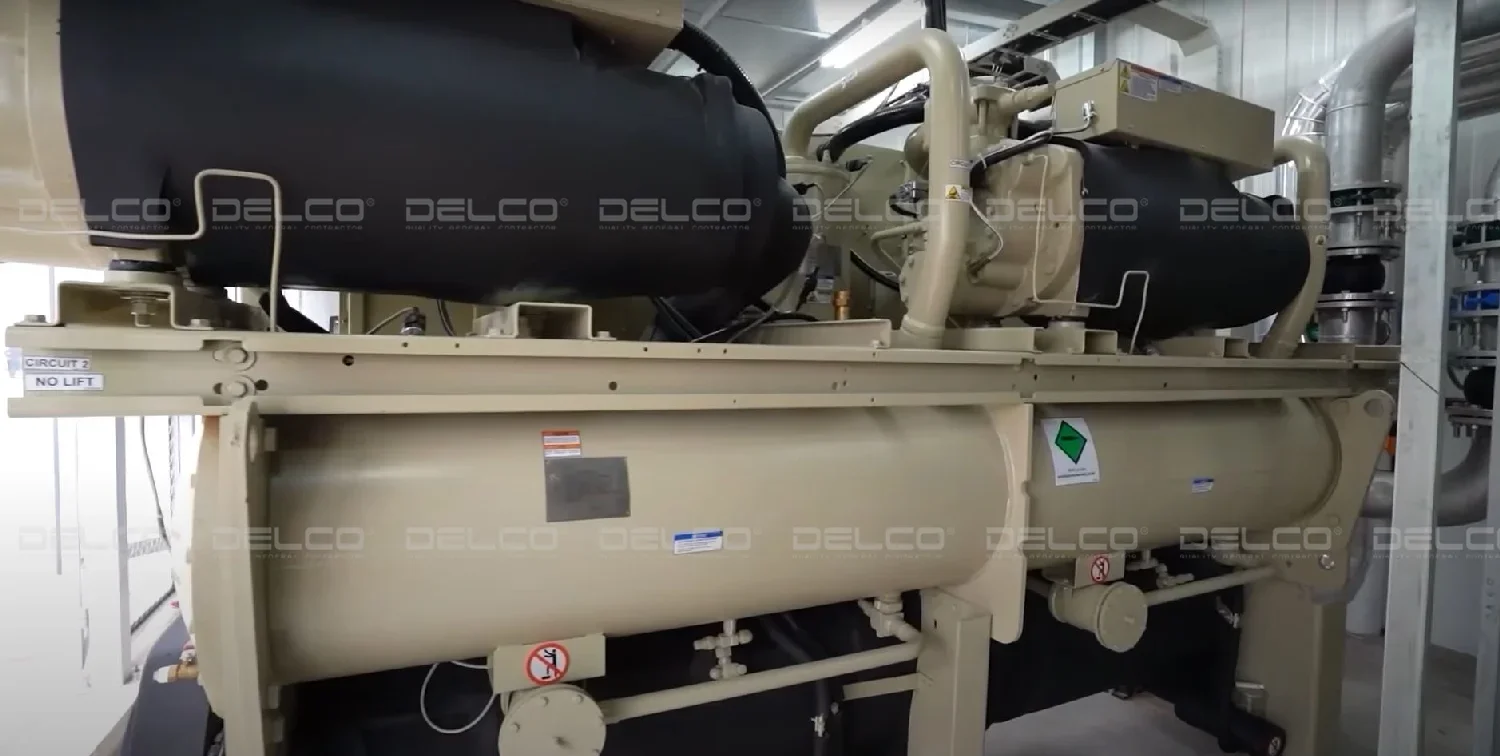

Chiller-based HVAC system at the Dainese Vietnam Factory – A project by DELCO as MEP General Contractor

- Direct Expansion (DX) system: Suitable for cold storage, small rooms, or localised cooling needs.

- Ammonia (NH₃) system: Used for large cold storage or freezing systems; energy-efficient but requires strict safety protocols.

- CO₂ cooling systems: Including CO₂/NH₃ cascade or CO₂ transcritical systems; a growing trend in the food and beverage industry.

CO₂ cooling system in use.

- VRF/VRV systems: Commonly used for office areas within factories or workshops with variable loads.

Central VRF air conditioning system at Toyo Solar Phu Tho Factory project by DELCO as Design-Build Contractor for factory interior.

- Free cooling chillers: Ideal for Northern Vietnam, taking advantage of cooler outdoor temperatures during winter to reduce compressor load.

- Glycol cooling systems: Use glycol as an intermediate fluid, commonly applied in the beer and beverage industry.

3. Cooling solutions for different industries

The food and beverage industry requires precise temperature control to preserve raw materials and finished products. Deep-freeze storage facilities often use screw-type NH₃ systems or NH₃/CO₂ cascade systems, while beer and soft drink production lines typically use glycol chillers for indirect cooling, which offer both safety and controllability.

In pharmaceuticals, all production areas must comply with GMP and cleanroom standards. Factories typically use water chiller systems combined with AHUs (Air Handling Units) equipped with HEPA or ULPA filters. Humidity control is handled by desiccant dehumidifiers to prevent product degradation.

Electronics and components manufacturing has even stricter requirements for humidity and particulate control. In addition to AHUs and HEPA filters, many factories install high-capacity dehumidifiers to maintain humidity levels below 40% RH, preventing damage to static-sensitive components.

In the mechanical and manufacturing sectors, cooling systems are mainly used to remove heat from machines such as CNC machines, injection molding equipment, and metal casting systems. Water-cooled chillers with cooling towers are commonly used, while air-cooled chillers are more suitable for small workshops or auxiliary zones. In factories with variable cooling loads, selecting chillers and pumps with variable speed drives (VSD/VFD) can significantly improve energy efficiency.

4. Optimizing performance and operating costs

Choosing the right contractor and construction plan

Selecting the right contractor from the early stages determines the long-term performance of the entire system. A contractor with experience in MEP systems can offer solutions tailored to your industry, optimize the design, and prevent both overinvestment and capacity shortages. In addition to technical expertise, relevant project references, and the ability to meet international standards, a critical factor lies in the proposed construction method and the warranty and maintenance plan included in the contract, ensuring stable and long-term operation.

Choosing the right cooling technology

Cooling technology must be selected based on cooling load, production requirements, and actual site conditions. For large, continuously operating factories, water-cooled chillers or NH₃ systems offer the best efficiency. Meanwhile, medium-sized workshops or supporting areas can use air-cooled chillers or VRF systems for more flexibility.

Applying smart control systems such as BMS or SCADA can improve monitoring and operational efficiency, but these should be considered during the overall design stage to ensure seamless integration.

Long-term operation and maintenance

A cooling system can only remain sustainable if it is paired with a clear operation plan and scheduled maintenance. Contractors should commit to providing ongoing inspection, maintenance, and monitoring services throughout the project’s lifecycle. This includes refrigerant leak detection, equipment calibration, and software updates. With the contractor’s long-term support, the system will operate smoothly, maintain high performance, and reduce the risk of unexpected downtime.

See more: Key international standards in factory fit-out

See more: Common types of industrial air conditioners for factories in Vietnam

See more: HVAC technology trends in Vietnam in 2025