Effective factory traffic management, from production layout planning to the design of entry/exit gates and internal traffic flow, can significantly impact productivity and operational costs in a factory.

Importance of Internal traffic design in factories

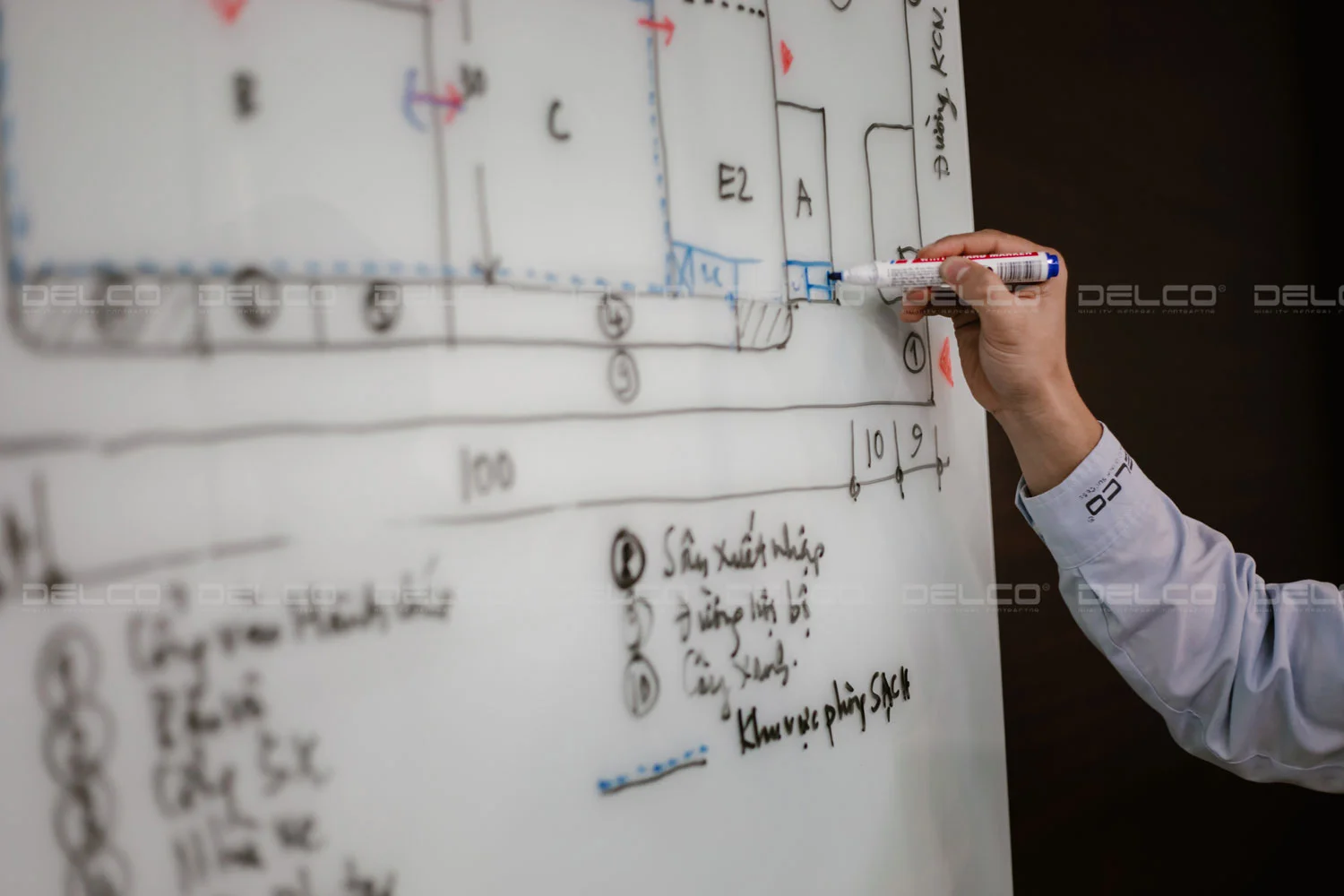

The internal traffic system is crucial for connecting production and operational areas within the factory. This includes all pathways for workers, designated routes for personnel movement, and lanes for machinery and goods transport.

Efficient and well-planned traffic design in an industrial facility can optimize production processes, reduce transport distances and waiting times, and facilitate seamless coordination between different factory departments, thereby enhancing productivity and lowering costs. Additionally, rational internal traffic planning improves workplace safety, minimizing the risk of incidents caused by congestion or collisions.

How to design effective factory traffic?

Reasonable production layout

Factory layout planning and design should ensure a logical organization of production spaces. Related production and operational areas should be located near each other. For example, the raw material storage area should be close to entry and exit gates to minimize transportation time and ease traffic flow on internal routes. Finished goods storage should be located near dispatch gates to streamline the movement of goods in and out. It’s essential to properly separate production areas and management offices, creating a comfortable working environment and ensuring employee safety.

Convenient loading and unloading gates

The placement of Loading and Unloading Gates should allow easy access from main roads and proximity to warehouse areas, optimizing the intake and dispatch of materials and goods.

Large doors in loading and unloading zones, where trucks and containers can directly access the factory, speed up and secure the loading process. Entry/exit operations should be systematically organized, with specific schedules for each vehicle type, color-coded road markings, or informational signs to facilitate traffic management and guidance within the factory.

The loading and unloading area at NITTOKU factory in Ha Nam is designed to allow direct access for trucks and containers, enhancing efficiency and safety in cargo handling.

Safe traffic flow segmentation

The layout of worker pathways within a factory should be clearly separated from the routes used by machinery and vehicles to prevent conflicts between pedestrians and moving equipment. Forklifts and other heavy-duty transport equipment should have designated lanes, reducing the risk of collisions and ensuring smooth operational speed, which enhances both efficiency and safety.

Worker pathways at Power Plus Technology are designed with covered walkways on dedicated routes to ensure safety.

Aesthetic and harmonious architectural design

The internal traffic layout should also be aesthetically pleasing and architecturally harmonious with the overall design of the factory. A unified approach to walkways, signage, lane dividers, and main traffic areas not only enhances the professional image of the business but also strengthens the brand image in the eyes of clients and partners visiting the factory.

See also: Office and canteen design standards in factories

See also: Detailed pricing for comprehensive factory design and construction services 2024