In industrial factories, energy is a core factor that directly affects both operational costs and production stability. As factories scale up and increase the number of machines and production lines, monitoring and managing energy consumption becomes more complex, requiring a systematic monitoring solution.

An Energy Management System (EMS) is implemented as a tool for collecting and analyzing energy data, enabling data-driven decision-making rather than relying on intuition. However, the effectiveness of EMS heavily depends on the factory’s operational characteristics, scale, and readiness—it is not always a necessary investment for every case.

What is EMS?

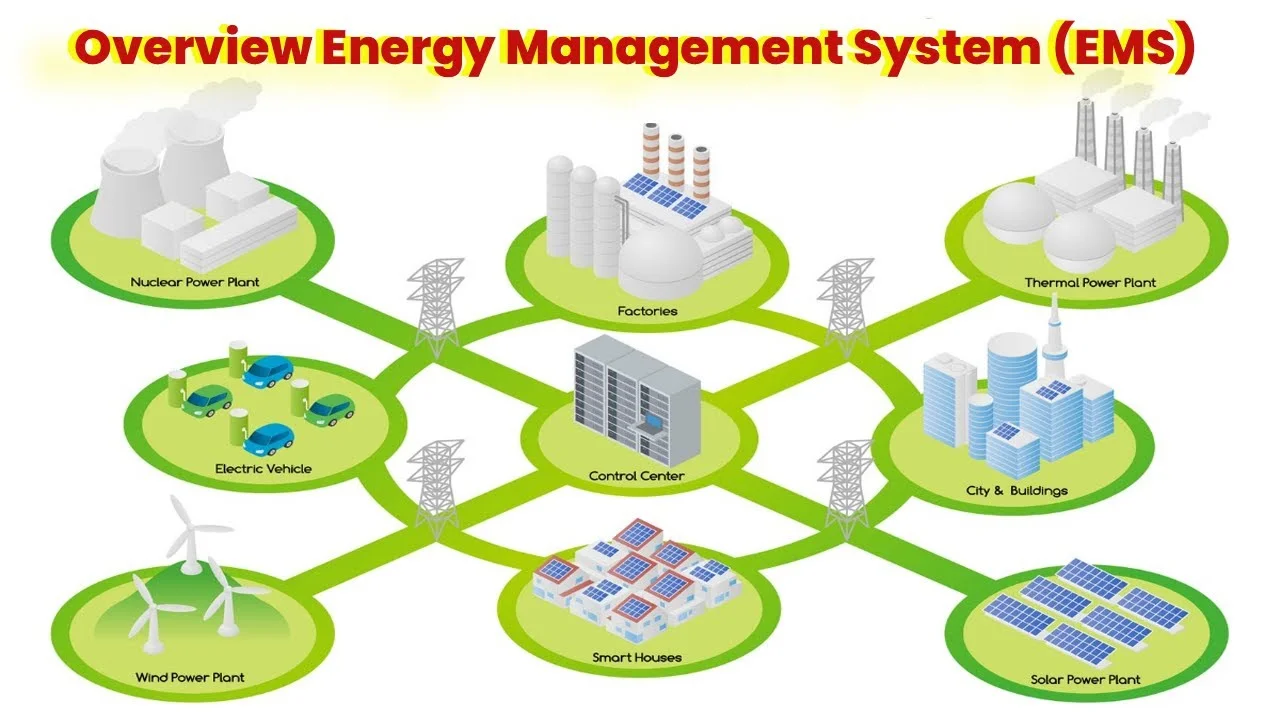

EMS is a system that collects, aggregates, and analyzes energy consumption data across the factory. This data is gathered from measurement points, meters, and related technical equipment, then processed to support monitoring and evaluation tasks.

Beyond just centralizing scattered data, EMS can also link energy data with equipment status and production activities. When placed in the right context, EMS becomes a decision-support tool, not just a data recorder.

When should EMS be implemented?

EMS is particularly effective in factories with complex operations, where traditional monitoring tools can no longer meet energy management needs. Suitable scenarios include:

- Factories with high energy consumption, where energy costs account for a significant portion of operating expenses

- Facilities with multiple areas, lines, or equipment groups with varying consumption patterns

- Energy usage fluctuates by shift, output, or product type

- Management needs to analyze, compare, and understand the reasons behind energy consumption changes over time

In such factories, EMS clarifies the overall energy picture, enabling operation adjustments based on data instead of perception.

When is EMS not necessary?

For small-scale factories with simple and stable production processes, energy consumption is often minimal and easy to monitor. In these cases, investing in EMS may not deliver value proportional to the deployment and operational costs.

Furthermore, if measurement systems are not standardized, data is inconsistent, or there’s no team responsible for analyzing and utilizing the data, then EMS may exist in isolation and fail to contribute to performance optimization.

Benefits of using EMS in a factory

The benefits of EMS are most evident when the system is properly integrated into the factory’s operational management model. EMS helps managers visualize energy consumption structures across areas, production lines, and process stages—revealing trends or anomalies that general reports may overlook.

In industrial projects, EMS is most effective when considered from the design phase, ensuring measurement systems, energy zoning, and data structures are aligned with future operations. When correctly implemented from the beginning, the collected data truly serves management purposes instead of merely providing tracking information.

When used consistently, EMS builds a data foundation for comparing different operational strategies, assessing the impact of technical or organizational changes on energy consumption. At that point, energy data goes beyond monitoring—it becomes part of strategic decision-making.

The value of EMS does not emerge immediately, but increases over time as data accumulates and operations develop the capacity to leverage it. EMS does not replace human oversight or operational processes—it expands the ability to control and adapt in increasingly complex production environments.