To avoid heat stress in manufacturing and industrial factories, it is necessary to combine many options, including anti-heat measures, from factory design to construction planning, selection of materials, installation of M.E.P systems, and considering how to reduce temperature in factory environments.

Factory planning – taking advantage of natural ventilation

Factory planning

When designing a factory in a climate area with a clear division between regions like in Vietnam, investors need to pay attention to the climate and weather characteristics of each region to have the most suitable plan. In most regions, the South and Southeast directions are the most favorable directions to build factories, with good ventilation and adequate light. In contrast, the West, East, Northwest, and Southwest directions receive a large amount of solar radiation, making the air in the factory very hot in the summer, which necessitates effective factory cooling solutions.

The reasonable layout of the workshop and ancillary items such as pump house, wastewater treatment area, etc. can also increase natural ventilation. The auxiliary areas are arranged in the direction of the sun to act as a buffer for the main workshop area, prevent heat radiation from the sun, and improve the heat resistance of the factory.

Landscape design with many trees of Power Plus Technology Smart Factory by DELCO is the Design – Build general contractor.

Reducing construction density, increasing the density of trees is also a meathod to reduce heat for the factory. According to Vietnamese Regulation QCVN 01:2021/BXD, the minimum percentage of land use for planting trees is of 20%. The investor can increase the percentage of trees to create a space to prevent the heat impact of solar radiation on the factory’s covering structure (reinforced concrete structure, corrugated iron, etc.). In addition, trees also help prevent dust and noise, contribute to air conditioning and create a landscape for the factory.

See also: The new points and notable changes of QCVN 01:2021/BXD on construction density

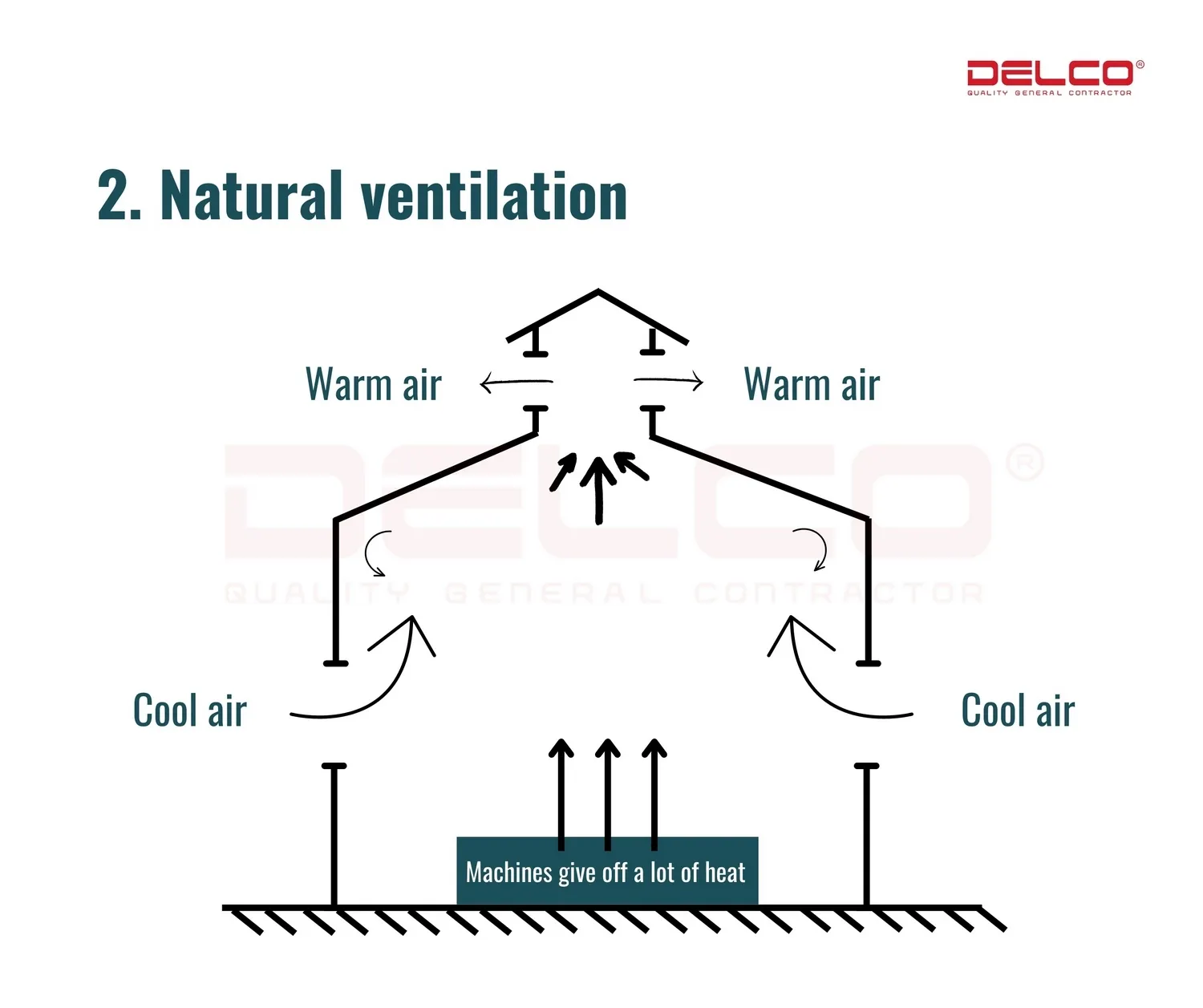

Natural ventilation

The arrangement of louver ventilators on the walls, skylights, roof doors, etc. reasonably will increase the ability of air convection, drawing cool air into the workshop and pushing hot air out. The air is always renewed due to the convection of the air in and out, creating a natural ventilation in the factory. Taking advantage of natural ventilation not only ensures a healthy production environment, but also helps the factory save energy and many other costs.

However, investors should research and survey carefully before choosing natural ventilation options. Manufacturing industries with strict requirements for cleanliness such as food factories, pharmaceutical factories, electronic factories, etc. should not use natural ventilation, because it can bring dust or impurities into the production environment, affecting product quality.

Factors affecting investors’ decision to rent a factory or construct a new factory

Using insulation – heat resistant

Brick wall

Fired bricks, autoclaved aerated concrete bricks, etc. are made of inert materials, so they have the ability to effectively insulate and resist fire.

In particular, autoclaved bricks are also a “green” material: produced from materials such as sand, cement, gypsum, lime, etc., when there is a fire or explosion, no toxic substances will be generated; The closed autoclaved gas process is an unburnt process that does not emit too much CO2 like other fired bricks. Autoclaved aerated concrete bricks will be the construction solution developed in the future.

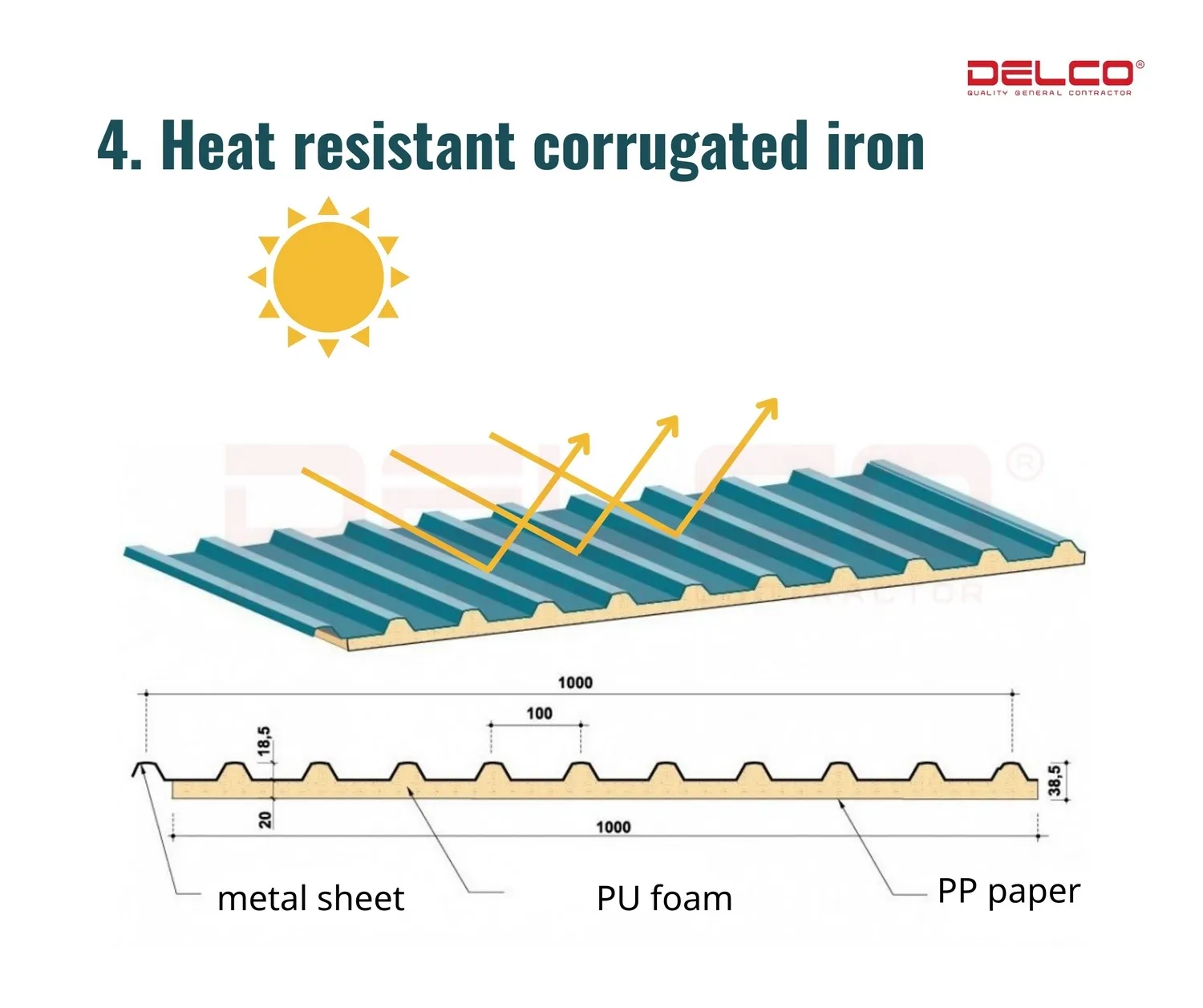

Anti-Heat Insulated Corrugated Iron

Anti-heat heat resistant corrugated iron is a roofing material created from a combination of colored cold corrugated iron, PU insulation, and a silver lining on the underside of the roofing sheet. This insulated roofing sheet is lightweight, easy to construct, requires a simple truss structure, and uses fewer purlins, saving 20-35% in costs compared to roofing tiles or other materials such as fibro, cement, etc.

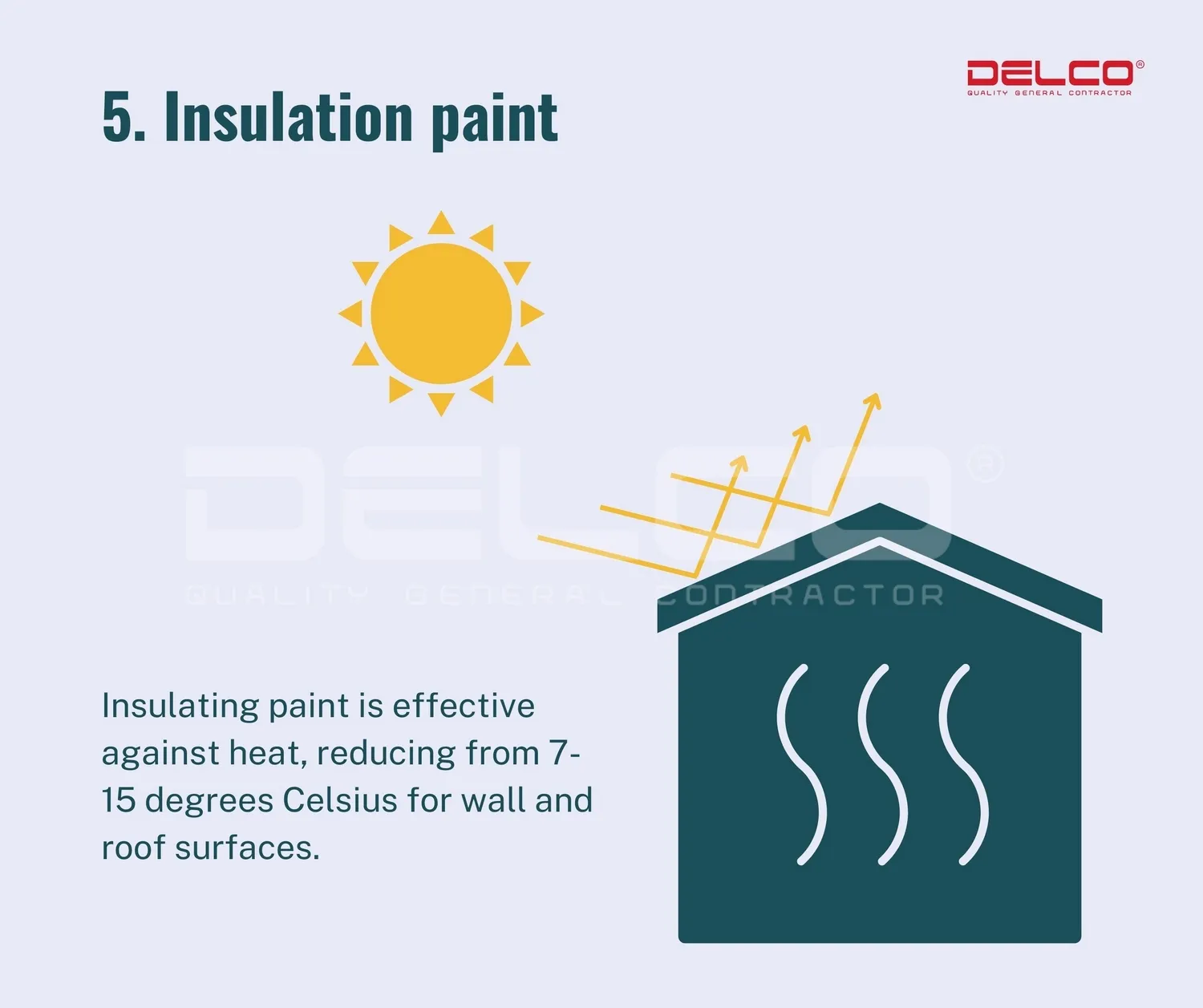

Insulation paint

Insulation paint, also known as heat-resistant paint, is commonly used for exterior walls, insulation for glass, corrugated iron, tiled roofs, flat roofs, etc. The paint is effective against heat, reducing from 7-15 degrees Celsius for wall and roof surfaces. Some heat-resistant paints are also waterproof, highly water-resistant and won’t peel or crack, helping to block UV rays and high heat radiation by up to 80%.

The cost of insulation paint is quite high. Some types of heat-resistant paint for corrugated iron roofs can be up to 3,000,000 VND – 3,500,000 VND/ 18 liter barrel.

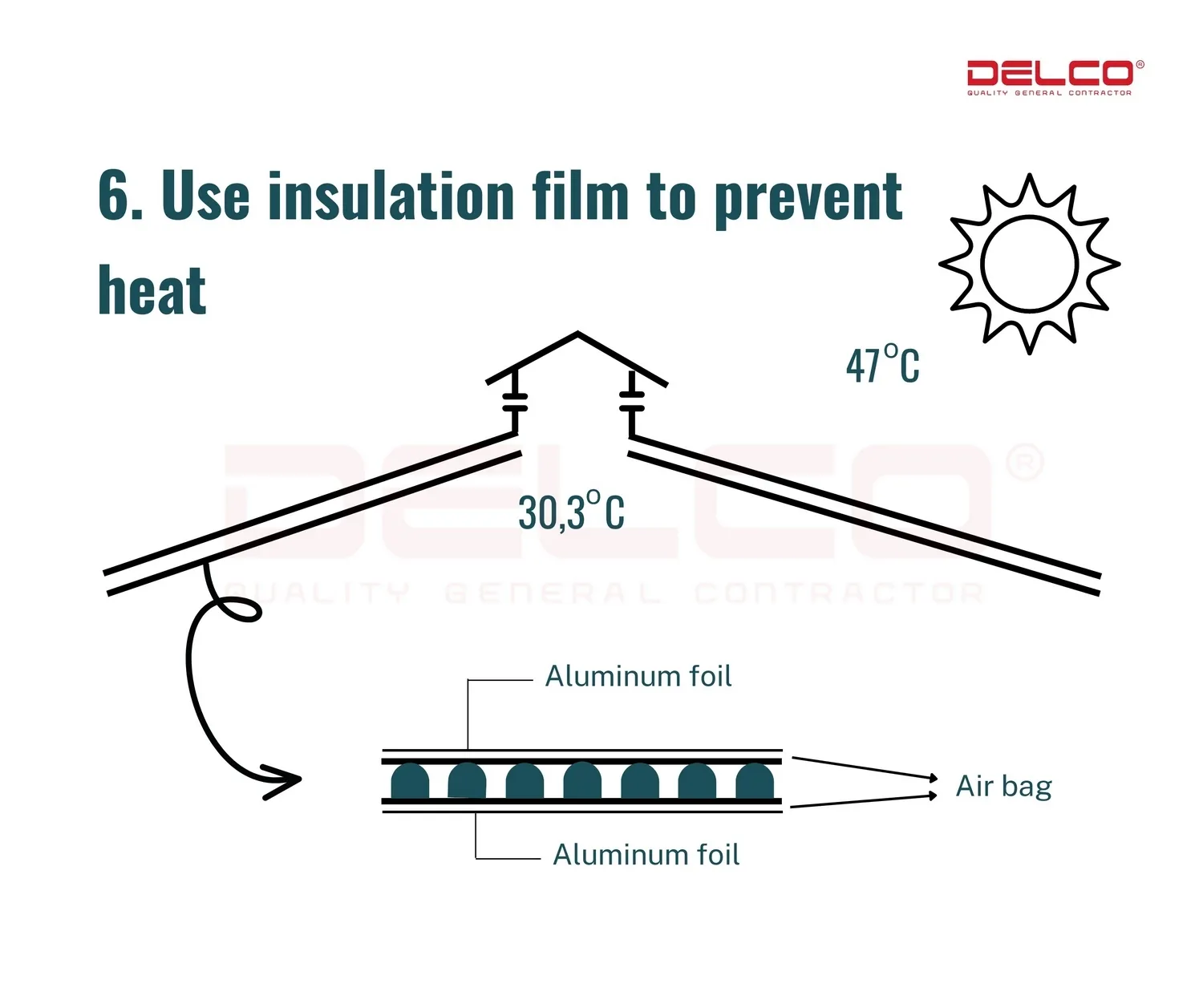

Use insulation film to prevent heat

It is an insulating sheet below the corrugated iron roof to reduce the amount of heat from the corrugated iron roof, preventing the amount of natural radiation from affecting the surrounding space. They are made of inorganic or organic materials with a coefficient of thermal conductivity not greater than 0.157 W/m.0C.

Forced air cooling methods in factory by M&E system – An Essential Factory Cooling Solution

Besides natural cooling, it is necessary to combine with forced cooling to increase efficiency, ensure worker health and quality of raw materials and finished products. This is an option to use electrical equipment such as fans, air conditioners, chillers, coolers… to cool the factory areas.

Installing misting system

The sprinkler system is fixed on the roof, and the amount of water being sprayed evenly throughout the roof will help cool the roof very quickly. This method is an effective answer to how to keep factory cool in summer, with the added benefits of low investment and operating costs, as well as environmental friendliness.

When operating the system, investors should pay attention to minimize excess water flowing to the roof, avoiding waste and unsanitary:

– Select the sprinkler with the largest spray diameter and small amount of water,

– Calculation to use water pump with suitable pressure and water flow,

– Allocate sprinklers on the roof reasonably.

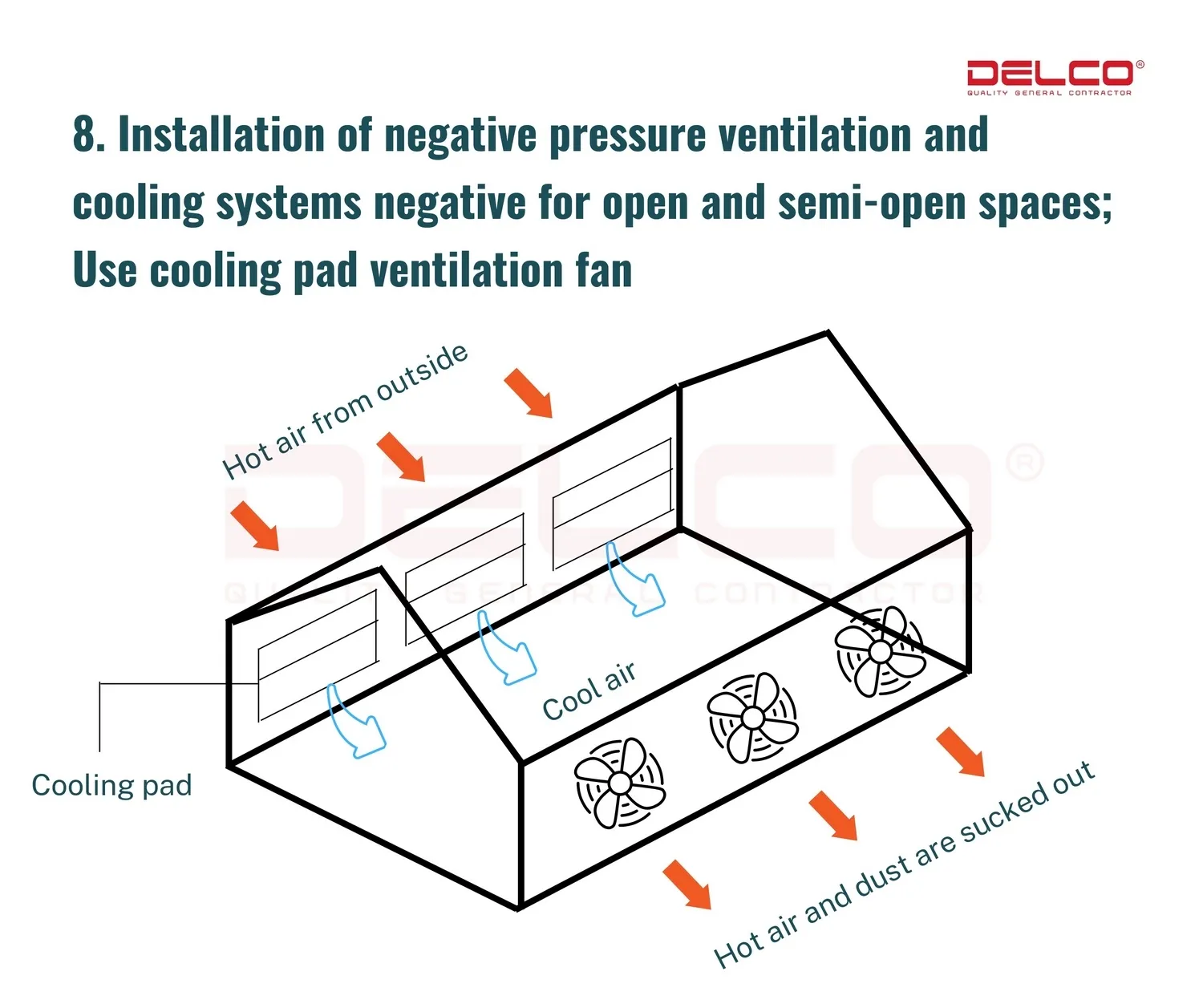

Installation of negative pressure ventilation and cooling systems negative for open and semi-open spaces; Use cooling pad ventilation fan

On one side of the factory, an exhaust fan system with large air volume is installed to suck all the hot, polluted air and industrial dust in the workshop and discharge it out. At the factory gable on the opposite side, install a heat exchanger frame system using a Cooling Pad. Taking advantage of the pressure difference inside and outside the factory, hot and dry air from outside is forced to pass through the Cooling Pads, exchange heat directly with water, becoming clean, cool and humid air, making effectively reduce the temperature in the factory.

This system is often applied to factories with a lot of smoke, high heat, and high noise levels such as textile factories, packaging, mechanical workshops, automobiles, industrial farms, etc.

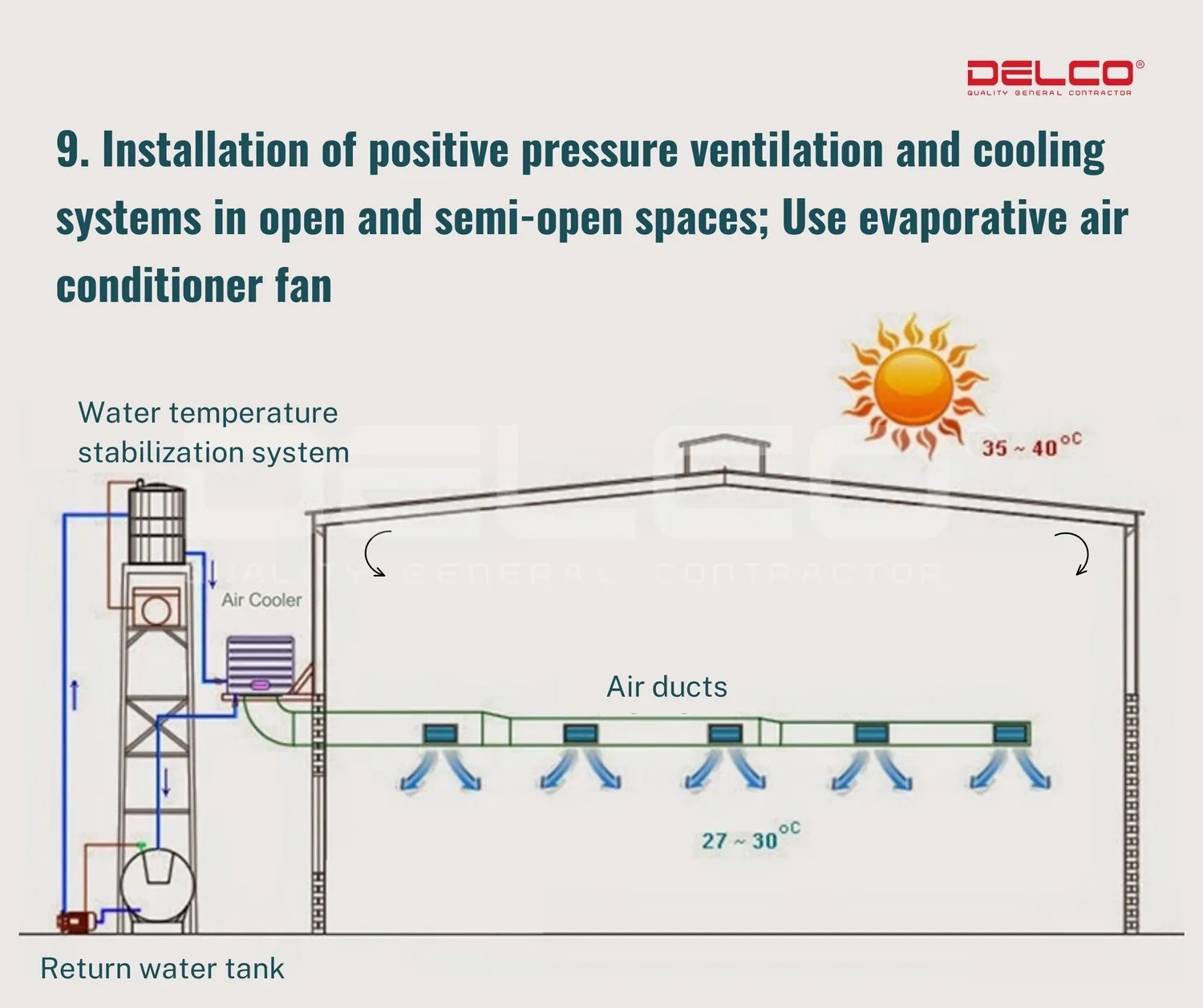

Installation of positive pressure ventilation and cooling systems in open and semi-open spaces; Use evaporative air conditioner fan

Contrary to the operating principle of the negative pressure cooling system, which takes advantage of the pressure difference inside and outside the factory, the positive pressure cooling system actively takes the fresh air outside and pushes it through the Cooling pad membrane to exchange heat. This cool air is pushed continuously by the fan into the factory through the system of air ducts. The hot air inside the factory will automatically escape through the windows, louver doors, roof doors, etc.

This system is suitable for installation in processing workshops with large areas, open and semi-open spaces, without generating much heat and noise.

Using industrial fans: Ceiling fans, standing fans, hanging fans…

Open-space factories such as wooden workshops, mechanical workshops, etc. or some small-scale production workshops, investors can consider installing industrial fans, ceiling fans, standing fans, wall fans, and ventilation fans, etc.

Although this is an easy method to implement, regardless of the design of the factory, saving cost, but it is only suitable for open space workshops with continuous air in and out. In addition, the noise from the fan motor also affects the production working environment, the fan blades will collect dust for a long time and it will incur frequent cleaning costs.

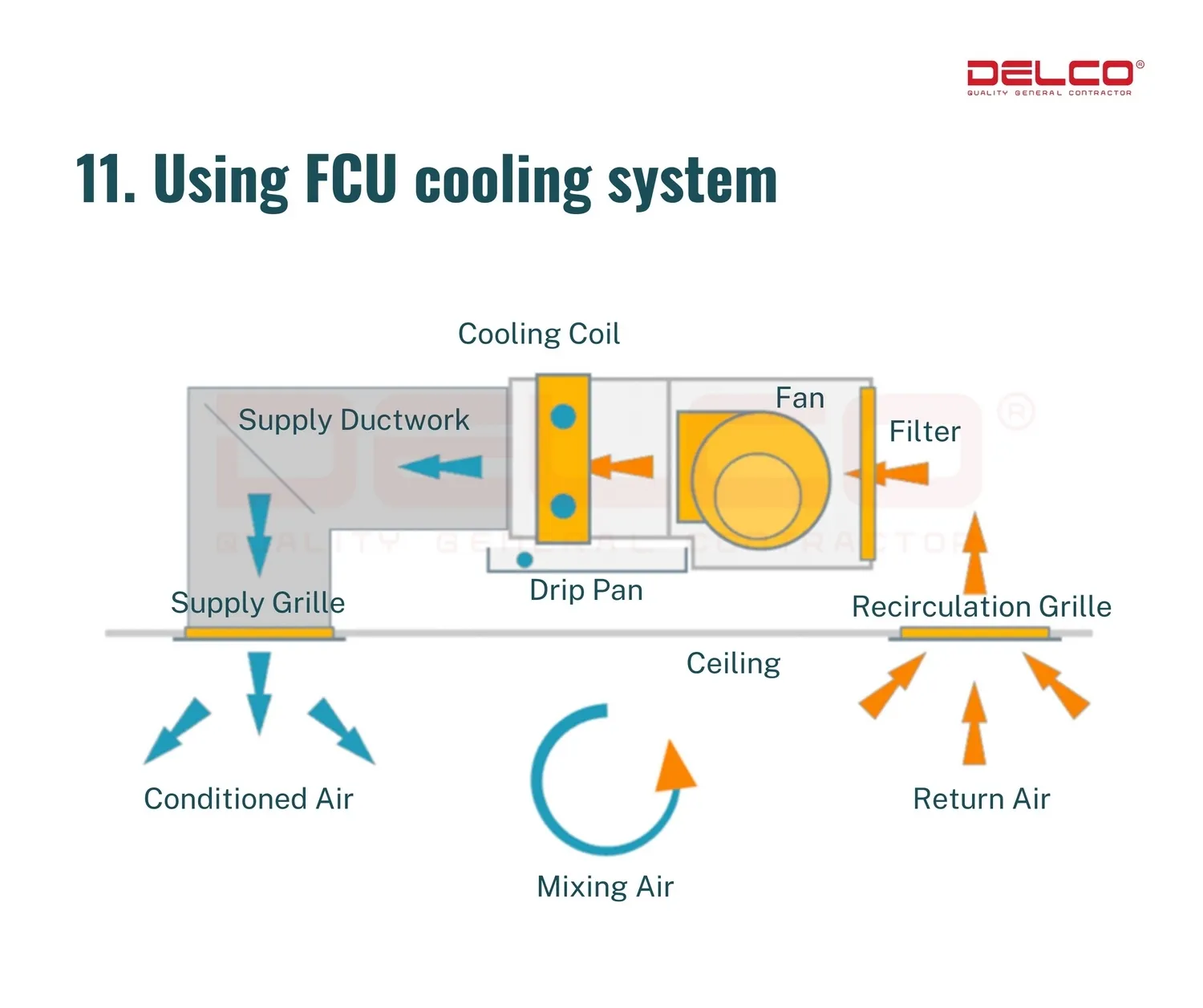

Using FCU cooling system

Factory space is not too large can use cooling solution by FCU (Fan Coil Unit). The FCU will return the air from the air-conditioning room through the Recirculation Grille, which is pushed by the fan through the FCU’s cooling coil to cool the air, dehumidify, and then be supplied back to the air-conditioning room through the supply air duct.

This is a cooling solution that can be applied to clean room areas of the factory, with a variety of designs, flexible use on all terrains of walls, closed ceilings and open ceilings. However, the investment costs and the ability to be environmentally friendly are the disadvantages of this method. Initial investment costs are quite high due to investment in heat treatment systems (Chiller, Cooling tower…), these systems need space outside the factory. During operation, the Chiller system, Cooling tower generates a large amount of heat and is discharged directly into the environment.

Installation of large capacity air conditioning system

This is a method of using an air conditioning system with a large capacity of 50,000 – 240,000BTU (average industrial air conditioning capacity), providing fast and strong cooling for the factory.

If you are looking for how to reduce heat in factory settings, air conditioners are an excellent choice as they reduce temperature faster than other cooling options and can easily regulate the exact temperature in the factory. They can be used for factory areas that require a constant temperature, strict standards on cleanliness, pressure, etc., such as electronic components factories, pharmaceutical factories, food factories, etc.

The option of installing an air conditioning system is a plan with a large initial investment cost, consuming a lot of electrical energy and continuously emitting hot air to the surrounding environment during operation.

Large capacity air conditioner at a commercial printing factory project in Hoa Mac Industrial Park, Ha Nam, by DELCO is the general construction contractor.

Combining heat-resistant options right from the design to construction and finishing stages in a reasonable manner will help the factory to effectively resist heat. Towards the goal of green industry development and the increasingly popular trend of green factories today, investors should consider prioritizing natural and environmentally friendly cooling options while optimizing costs, ensuring the working environment and employee productivity, and ensuring the production quality of the factory.