Solar power systems directly impact the design and operation of factory MEP systems. Without proper calculation and synchronized implementation, investors may face serious technical and safety risks.

Consider rational arrangement of electrical systems to ensure stable grid connection

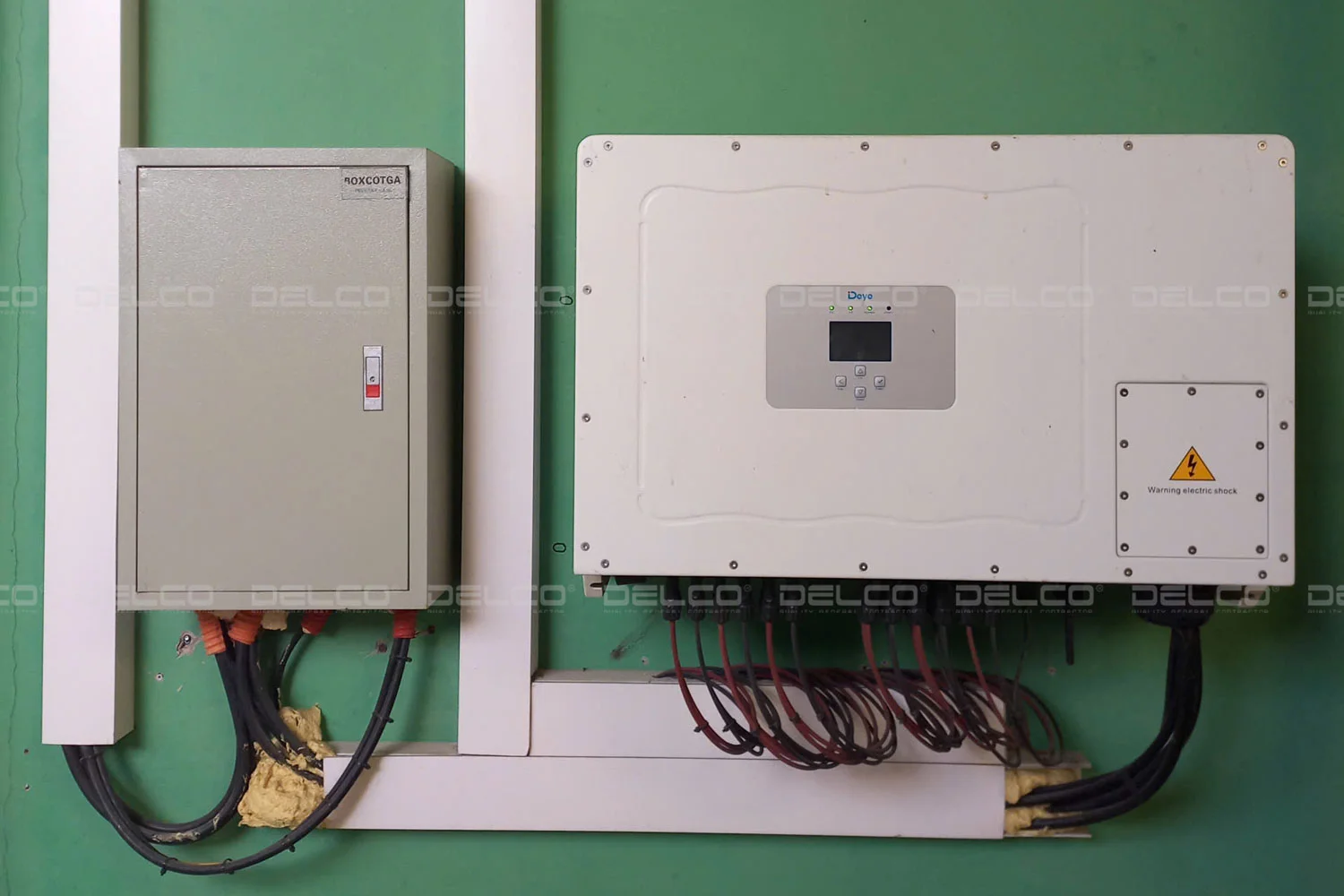

A factory solar power system consists of multiple technical components such as inverters, electrical cabinets, cable systems, etc. These must be arranged logically to avoid affecting production space and machinery operation.

Solar power output is heavily dependent on weather conditions and often unstable. Cloudy or rainy days will reduce production capacity. Therefore, the grid must still ensure sufficient power for the factory to maintain continuous production. In many cases, investors should also consider installing battery storage systems to optimize power use during peak hours or grid outages.

Consider synchronization with other technical systems

When integrating solar energy into factory design, the solar power system must be closely coordinated with other technical systems to ensure safety and efficiency.

- Fire protection system: must include fire spread prevention solutions in case of electrical incidents, ensuring safe exits.

- Grounding and lightning protection: solar panels and metal frames increase lightning discharge risks. Grounding and lightning protection design must be upgraded accordingly to protect the entire factory.

Consider operation and maintenance safety

The factory solar power system operates continuously outdoors, posing risks of short circuits, overload, or fire. Therefore, MEP design must include safety devices such as rapid shutdown systems, temperature monitoring sensors, and incident response procedures.

In addition, selecting high-quality solar panels and inverters with clear origins, along with regular maintenance, is key to ensuring long-term durability and efficiency. Standard panels have a lifespan of over 25 years, while inverters can last 5–10 years depending on type and operating conditions.

The inverter system at DELCO Farm – Bac Ninh ensures stable conversion efficiency, effectively harnessing renewable solar power.

Consider permits and grid connection procedures

Besides technical factors, investors must understand legal regulations when connecting solar systems to the grid:

- Capacity < 100 kW, no selling surplus electricity: only notification is required for the utility to inspect and confirm safety before connection.

- Capacity ≥ 100 kW or selling surplus electricity: depending on scale, businesses must register for development and may need an Electricity Operation License.

- Capacity ≥ 1,000 kW or selling surplus electricity: full procedures are required, including development registration, electricity operation license, environmental documents, construction permits, and a power purchase agreement with EVN.

Investors should work with legal consultants initially and EPC contractors to comply with regulations and ensure timely grid connection aligned with project schedules.

See more: Does the solar power trend change factory architecture and structure?

See more: Installing a solar power system at DELCO Farm: Toward sustainable and cost-effective operations