Vietnam sets the goal of non-fired building materials accounting for 35-40% of the total number of bricks produced in the country by 2025, reducing CO2 emissions to over 2.5 million tons/year by 2025 and over 3 million tons/year by 2030.

What are green building materials?

According to the VietNam Institute For Building Materials and Equipment, Environment and Labour Safety Center, green building materials are understood as types of materials that use natural resources in an environmentally friendly manner, with the ability to be recycled and decompose naturally.

Green building materials must meet at least one of the following criteria: made from recycled materials and be recyclable, free from toxic substances, have a long life cycle, resource-efficient, and effective in energy and water usage, etc.

In Vietnam, the trend of using green building materials is increasing in popularity, many large businesses choose to build green factories in Vietnam, such as Coca Cola, Heineken, Ajinomoto Vietnam, etc. To promote the use of green building material projects, the Ministry of Construction issued Circular 13/2017/TT-BXD stipulating that from February 2018, all projects with state capital greater than 30% must use non-fired building materials.

Vietnam has also launched a strategy to develop the construction industry until 2030, aiming towards 2045 with the goal of non-fired building materials accounting for approximately 35 – 40% of the total number of bricks produced in the country by 2025 and reaching 40 – 45% by 2030. The target for reducing CO2 emissions by 2025 is over 2.5 million tons per year and by 2030, it is over 3 million tons per year (compared to the equivalent volume of fired bricks).

See more: Factors affecting factory construction cost

Green building material standards

Currently, in Vietnam as well as in countries around the world, there are no specific standards for green building materials. However, some existing green building certificates have regulations on the origin and index of construction materials.

Some green certifications are accepted and widely used by many countries, typically the US LEED certification issued by USGBC. To achieve this certification, construction materials of green projects must be sourced from natural origins, be recyclable, and not contain harmful substances such as formaldehyde and VOCs (Volatile Organic Compounds), etc.

In addition, the Vietnam Green Building Council has also developed the LOTUS green building certification specifically for the construction market in Vietnam. Buildings that meet the LOTUS standard must use construction materials that are sustainable and recyclable, with minimal use of concrete and fired materials.

Furthermore, the Vietnam Institute for Building Materials has also issued criteria for assessing green cement according to Decision No. 201/QD-VLXD dated September 29, 2022, by the Ministry of Construction. Specifically, green cement needs to meet certain conditions regarding the use of alternative raw materials/fuels, energy consumption and emission levels set by the Institute of Construction Materials.

| Assessment criteria | Value |

| 1.Requirements for using alternative raw materials and fuels | |

| Use alternative fuels | Up to 15% |

| Or use industrial waste as an alternative material | At least 39% |

| 2. Energy consumption and emission levels | |

| a.For clinker production process | |

| Heat energy consumption | ≤ 800 kcal/kg clinker |

| Power consumption | ≤ 65 kWh/ton clinker |

| Emission levels in kiln exhaust gases | + SO₂ ≤ 200 mg/Nm³ + NO₂ ≤ 800mg/Nm³ + Dust ≤ 30mg/Nm³ |

| b.For cement grinding process | |

| Power Consumption | ≤ 40kWh/ton of cement |

| The amount of CO2 emissions during the cement production process. | ≤ 650kg/ton of cement |

Some assessment criteria for green cement materials by the Vietnam Institute for Building Materials.

Popular green building materials in Vietnam

Non-fired bricks

Non-fired bricks are one of the green building materials used as a substitute for conventional fired bricks in industrial construction projects, typically projects with state capital. This type of brick has good soundproofing, heat insulation, fire and moisture resistance, and is especially environmentally friendly because it does not undergo firing processes.

Non-fired bricks are made from waste materials, by-products, or aggregates such as stone chips, cement, etc. They are shaped and cured without the use of heat. Currently, there are many common types of non-fired bricks such as concrete bricks, slag bricks, autoclaved aerated concrete, etc. Depending on the construction requirements of each project, investors can choose the most suitable type.

Green cement

Green cement is a material produced from fly ash, a by-product of industrial production, researched and developed by The Trenchless Technology Center (TTC) at Louisiana Tech University in the United States. This material has higher friction resistance, better fire resistance, and higher tension and deformation compared to conventional cement.

Green concrete

Green concrete is formed through the mixing process of cement, stone, sand, water, ash, and bonding additives… The main components of green concrete are green cement and ash, as well as coal slag. This helps minimize the amount of ash and slag released into the environment, helping to save resources and protect the environment.

Green concrete has high durability, and its other properties are evaluated to be superior to those of conventional concrete, especially in terms of long-term durability.

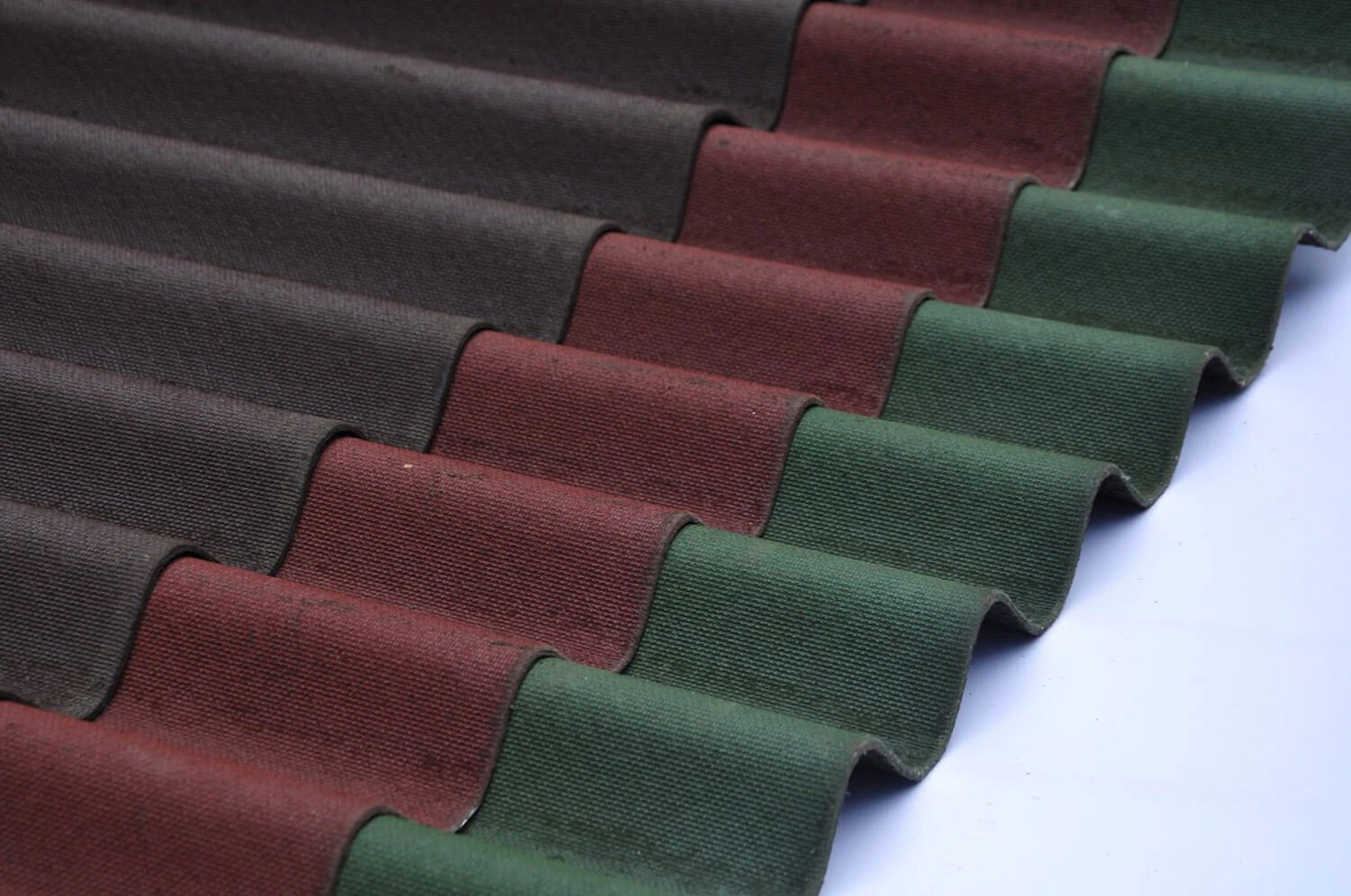

Organic Fiber Roofing Sheet

Organic Fiber Roofing Sheet is one of the green building materials, very lightweight, produced from organic materials such as cellulose, acrylic, and asphalt waterproofing material by mass pressing method. This type of material has good soundproofing, heat resistance, helps save energy effectively as well as withstands harsh weather and is non-corrosive, suitable for projects located near the sea.

Eco-friendly paint

Eco-friendly paint is a type of paint that does not contain harmful substances such as APEO, Formaldehyde, heavy metals, and low amounts of volatile organic compounds. This type of paint can be applied directly without a primer, is easy to apply, quick-drying, Able to resist all weather effects, protect against radiation and waves harmful to humans, absorb CO2, and has a durability of up to 25 years.

See more: Elastic coating paint: An appropriate selection for workshops, factories in tropical climate regions