At DELCO, occupational safety isn’t just a formality—it’s a core requirement on every construction site.

I’ve been a construction engineer for nearly 10 years, working on projects of all sizes and under various conditions. I know the pressure is always there—from tight schedules and heavy workloads to harsh weather. But no matter the circumstances, safety must always come first. A single lapse can lead to serious consequences: injuries or even fatalities, property damage, project delays, and loss of reputation. These are risks no one can afford.

At DELCO, safety is part of our daily work culture. We don’t treat occupational safety as a checkbox task. Our safety procedures are strictly implemented and form an essential part of how every job site operates.

- 100% of workers receive occupational safety training before starting work, sign a commitment to follow on-site safety regulations, and are fully equipped with personal protective equipment (PPE) that fits properly and meets required standards.

- Each workday begins with a brief safety briefing for engineers and workers, updating them on the day’s potential risks and reviewing safe operating procedures. Every construction site maintains its own safety logbook, recording daily safety measures tailored to specific tasks.

|  |

- Every DELCO construction site is equipped with a complete system of clear safety signs and regulations, which are placed in easily visible and accessible locations.

- The site management office is always equipped with a first-aid kit, emergency contact numbers, and basic first-aid instructions.

|  |

- Each construction site is equipped with 24/7 surveillance cameras, along with a walkie-talkie communication system that enables engineers and safety officers to respond quickly and coordinate effectively in any unexpected situation.

- All equipment and machinery—such as tower cranes, trucks, forklifts, and excavators—must be fully inspected and certified before use.

|  |

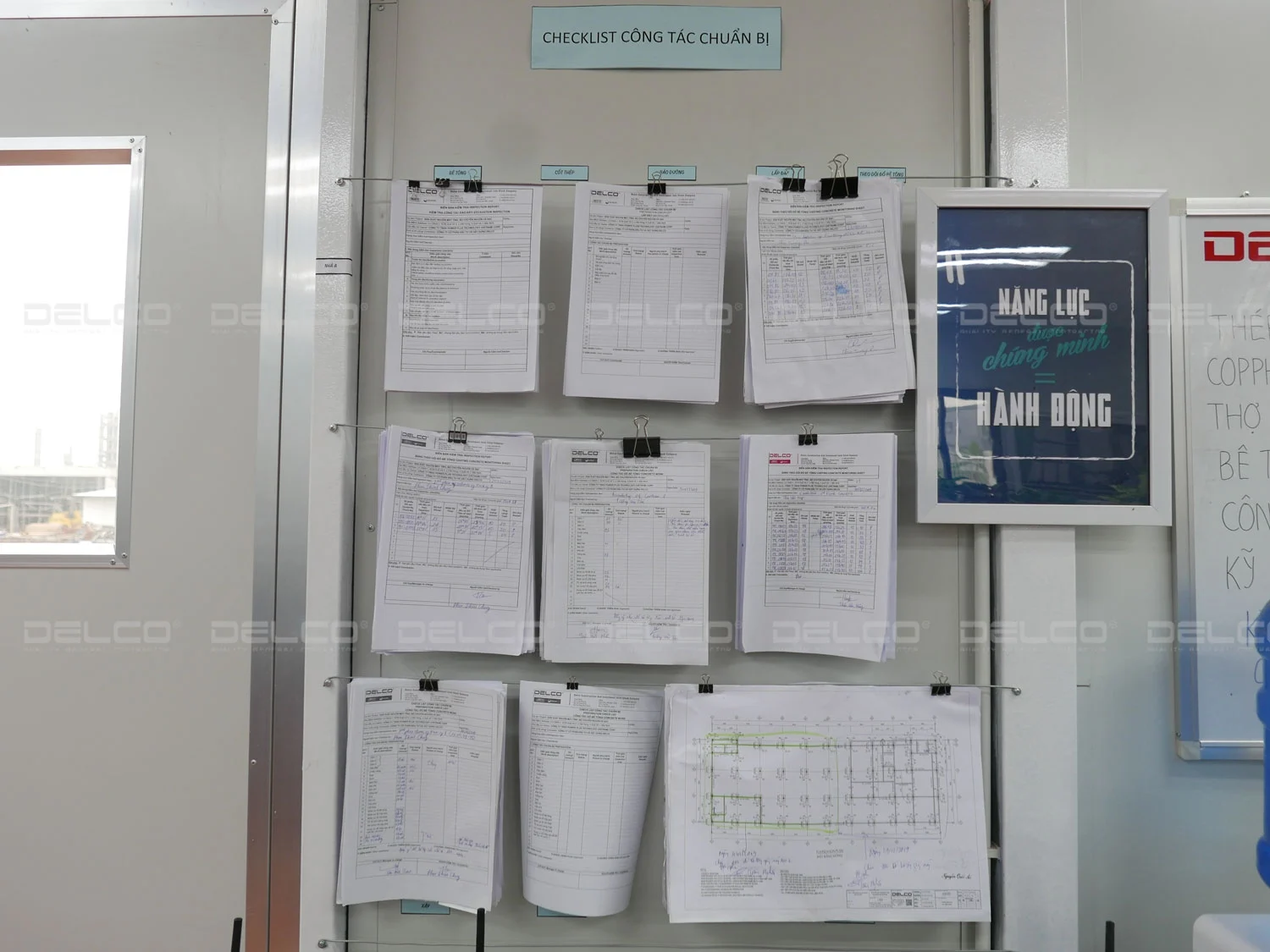

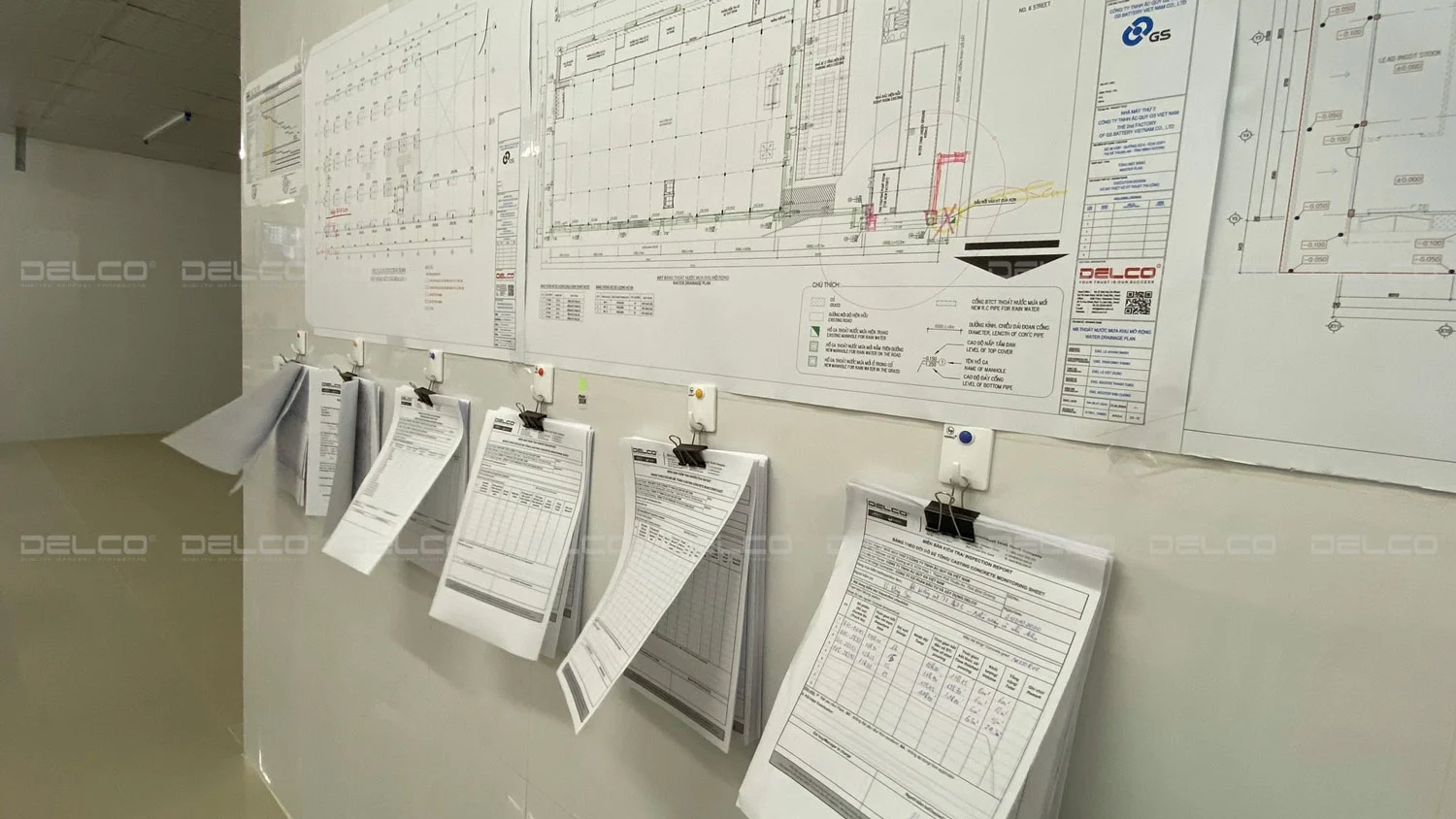

- Every DELCO site office is stocked with the necessary forms and safety checklists for pre-task inspections. Any equipment, scaffolding, or electrical systems that have not passed safety inspections are strictly prohibited from use.

|  |

- Each type of task, from excavation and foundation work to concrete pouring, plastering, and working at heights, etc. follows its own dedicated safety procedure, closely monitored by trained safety personnel.

- All welding and metal cutting activities must be properly shielded, with fire extinguishers and fire-resistant blankets in place, and factory fire safety inspections must be conducted before, during, and after the work is performed.

- After welding pipe systems, weld joints must undergo pressure testing and inspection in compliance with technical standards and occupational safety regulations.

- Designated smoking areas are clearly separated from flammable material zones and are equipped with fire extinguishers.

- DELCO regularly organizes fire safety training and emergency drills to improve real-life response skills for all personnel on site.

And there are many other detailed safety regulations that must be strictly followed…

t every DELCO project, safety is always the top priority—not just through procedures, but through a mindset of professional responsibility. Maintaining a strict and consistent occupational safety system allows DELCO to ensure a safe working environment while also reinforcing its commitment to project timelines, quality, and credibility.

L.D – Construction Engineer at DELCO Construction

See more: Ensuring safety of factory construction in extreme heat conditions

See more: Ensuring safety of factory construction during rainy & stormy seasons