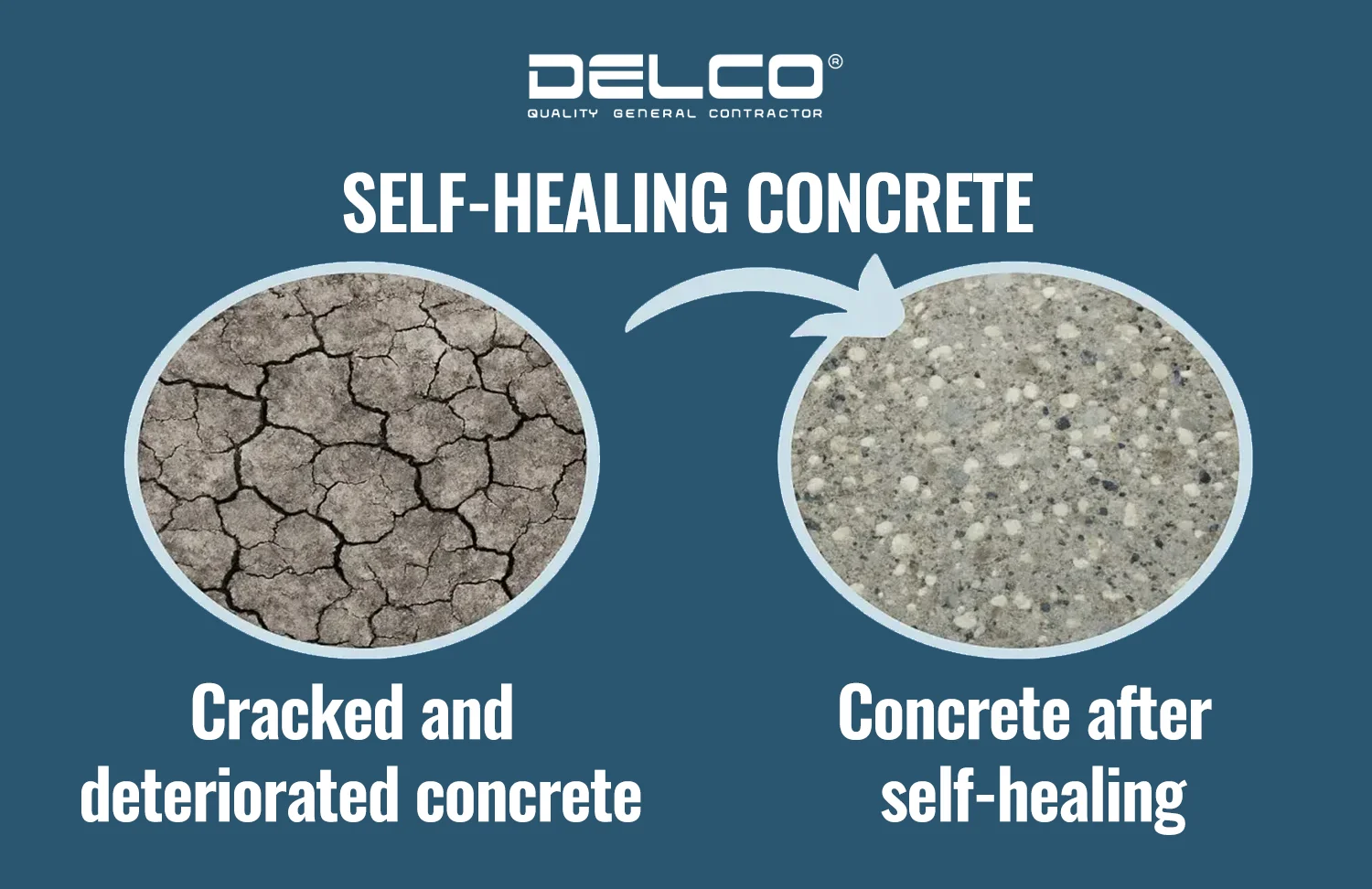

With the ability to repair cracks on its own through integrated chemical reactions or microorganisms, self-healing concrete is emerging as one of the most advanced materials being researched and applied in many countries, offering the potential to transform the way buildings and infrastructure are constructed and maintained in the future.

What is self-healing concrete?

Self-healing concrete is a type of concrete designed to automatically seal small cracks that form during use, without the need for manual intervention. Depending on the technology applied, the healing process can occur through:

Types of self-healing concrete

Depending on the operating mechanism, self-healing concrete is divided into the following types.

Bacteria-based self-healing concrete (also known as bio self-healing concrete) uses bacteria (often Bacillus) to produce calcium carbonate that fills small cracks.

Microcapsules-based self-healing concrete contains polymer microcapsules or polymer adhesives that bond themselves when a crack occurs.

Self-healing concrete using calcium carbonate crystallization takes advantage of the natural crystallization reaction of calcium carbonate from mineral ions (such as silicates and aluminates) already present in the concrete. This process mimics the mechanism of coral reef formation, enabling the concrete to heal itself, resist water penetration, and prevent corrosion. It is suitable for underground structures, basements, cold storage facilities, or coastal environments.

Self-healing concrete using nanoparticles employs nano silica or nano titanium with the ability to detect and seal ultra-small cracks while also enhancing durability and corrosion resistance. This technology is being tested for structures requiring extremely high stability such as chemical plants or defense projects.

Outstanding advantages of self-healing concrete

Increased structural lifespan: Self-healing concrete helps extend the service life of structures by preventing cracks from spreading and limiting the intrusion of water and corrosive gases.

Reduced long-term maintenance costs: The ability to automatically seal small cracks allows the concrete to maintain its strength and water tightness over time, thereby reducing the frequency of manual repairs.

In an application in the Netherlands, Basilisk’s bacteria-based healing technology was used on the Hoogwaardig Openbaar Vervoer Schiphol bus lane, extending its service life by at least 15 years. The project achieved remarkable results: about 33% reduction in life-cycle costs, over 90% reduction in CO₂ emissions, and shorter repair times.

Waterproofing and corrosion resistance: By sealing microcracks, self-healing concrete reduces the penetration of water and gases, thereby protecting the internal steel reinforcement from corrosion. Some technologies also allow the material to self-heal in high-humidity or seawater environments, making it especially suitable for coastal structures and underground infrastructure.

Sustainability and environmental friendliness: Self-healing concrete extends structural lifespan and reduces the need for cement production and use—cement accounts for about 8% of global CO₂ emissions. Some microbial systems used in concrete can even precipitate calcium carbonate by consuming CO₂ from the environment during their life cycle.

Application of self-healing concrete in construction

Self-healing concrete is applied in structures that require high durability and are difficult to access for maintenance, such as underground tunnels, overpasses, water tanks, coastal structures, and industrial plants. Its ability to seal small cracks helps prevent water and gas penetration, protect reinforcement steel, limit corrosion, and extend the structural lifespan.

The use of this material significantly reduces repair costs and construction interruptions caused by maintenance. This is a major advantage for facilities that operate continuously, such as factories, pumping stations, or transportation infrastructure projects.

A tunnel in Rijen, the Netherlands, used bio self-healing concrete, reducing reinforcement steel by 35% and extending the service life of the structure.

The first project to use self-healing concrete for a water culvert in Australia was carried out in 2022 by Professor Yan Zhuge, an engineering expert at the University of South Australia.

In addition, self-healing concrete is also suitable for projects aimed at sustainable development. Reducing maintenance needs and extending service life helps lower CO₂ emissions throughout the building’s lifecycle, in line with green building standards and modern construction trends.

Cost of self-healing concrete

Similar to many other advanced material technologies, the production cost of self-healing concrete is currently high because special agents such as bacteria or chemical microcapsules are not yet mass-produced. As a result, the price of this material can be 25–100% higher than that of conventional concrete, limiting its widespread application. However, research institutes and companies in the Netherlands, the United States, Japan, China, and other countries are actively improving technology to optimize production processes while seeking more cost-effective alternatives. Once the technology matures and reaches industrial scale, self-healing concrete is expected to become a common material choice, contributing to sustainable, safe, and cost-efficient industrial structures in the long term.

See also: Vinyl flooring – Anti-static material for safe working environments

See also: Elastic paint: An ideal solution for factories and industrial buildings in tropical climates

See also: The potential of graphene – the hardest material in the world