During the production process of factories or areas that require anti-static properties, Vinyl flooring serves as a supportive solution by providing anti-static features on the floor surface, preventing damage to products, and ensuring safety for users.

Vinyl Flooring – Anti-Static Material for factories & workshops

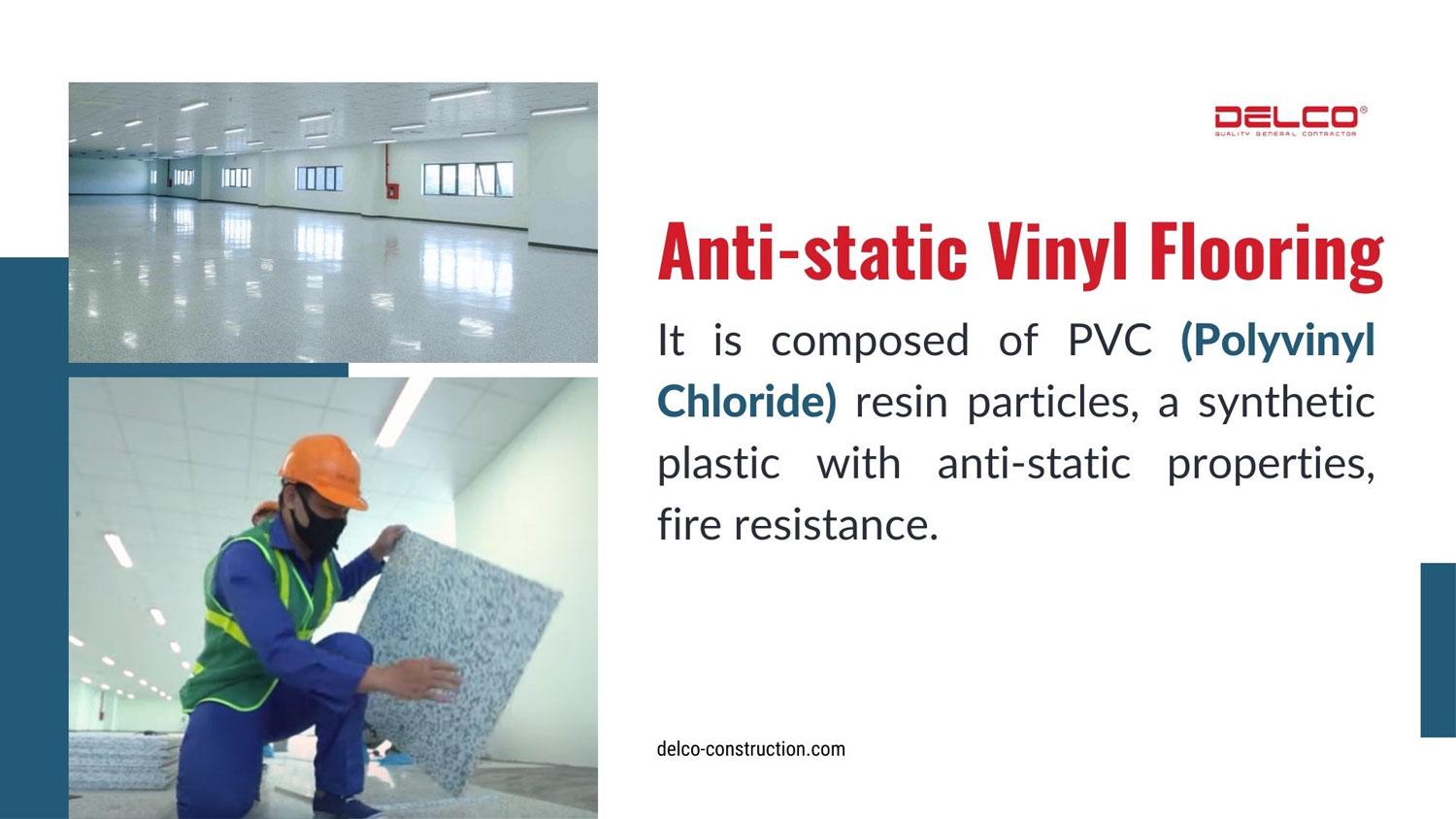

Vinyl flooring, also known as PVC flooring, is an anti-static flooring solution.

Anti-static vinyl flooring comes in the form of tiles (rectangular, square) or rolls, and is composed of polyvinyl chloride resin particles – a synthetic plastic with anti-static properties, fire resistance, and commonly used in cleanroom environments or in manufacturing and assembling electronic components factories,..

The anti-static mechanism of Vinyl flooring

During the manufacturing process in factories, the regular movements of workers themselves generate static electricity. This static electricity can potentially cause explosions and damage electronic circuits in factories, workshops, and assembly lines for electronic components and electronic devices. Therefore, Vinyl flooring is a suitable choice for factories and workshops, especially in cleanroom environments and high-tech manufacturing facilities. It offers anti-static properties on the surface, providing not only aesthetic appeal but also ensuring safety and convenience.

Anti-static PVC flooring is designed with a special structure to minimize static electricity. The electrical charge generated by static electricity during the normal movements of workers is conducted through a dedicated copper wire system to grounding boxes. Through this process, static electricity will be effectively eliminated, preventing explosions and ensuring the safety of products without posing any health risks to workers.

Advantages of Vinyl flooring

Besides the anti-static properties, Vinyl flooring offers several other advantages:

– Ensures long-term stability of the surface’s electrical resistance, the maximum durability can reach up to 10 years.

– Complies with the B1 fire protection standard (BIN 4102), offering fire resistance and preventing fire spread.

– Resistant to wear and dust, keeping the surface clean and easily maintainable.

– Convenient installation: Anti-static vinyl flooring can be installed even in narrow spaces, making it convenient for space layout during construction.

– Easy cleaning: Vinyl flooring can be easily cleaned with water and common household cleaning agents without affecting its anti-static properties.

– Easy maintenance and repair: When a vinyl tile is damaged, it can be easily replaced and re-welded, saving time and repair costs.

Suitable projects for using Vinyl flooring

Manufacturing and assembling electronic components factories

In manufacturing and assembling electronic components factories, static electricity can cause issues such as adhesion (attracting particles to the surface of static-charged objects) and electrostatic discharge, which can impact the printing and assembly processes and damage components and machinery.

Therefore, implementing measures to prevent static electricity and adhering to anti-static principles are essential in these factories. Using anti-static vinyl flooring in the design – construction of factories is a suitable solution that is easy to install and maintain.. Using vinyl tiles in manufacturing and assembling electronic equipment offers benefits such as static electricity prevention during production and product assembly, ensuring fire safety, resistance to wear and tear, easy replacement, and maintenance.

Vinyl flooring is used in the HAEM VINA 2022 Electronic Component factory – Design – Build Contractor DELCO.

Hospitals

The healthcare environment, specifically hospitals, clinics, dental offices, or aesthetic institutes, is a specialized setting with strict requirements. They often come into contact with cleaning agents and experience high foot traffic and heavy equipment movement. Therefore, the use of Vinyl flooring ensures that the surface is resistant to scratches and damages caused by cleaning agents or equipment used during the work process. This ensures durability and aesthetic appeal of the floor surface in a hospital environment.

In hospitals, Vinyl flooring is commonly used due to its antimicrobial properties. Hospitals are environments that harbor various types of bacteria and are prone to infections. Vinyl flooring not only has strong antimicrobial properties but also resists chemicals, making it highly suitable for hospital and healthcare environments.

Laboratories

Laboratory environments involve the use of various chemicals that can be flammable or hazardous, along with the occurrence of static electricity that can cause damage to equipment. Prolonged exposure to these factors can have a significant impact on human health.

The use of Vinyl flooring helps to dissipate the static electricity generated in the laboratory, protecting the floor from wear, scratches, and chemical damages. It allows for easy cleaning and sanitation using common cleaning agents without compromising its durability.

Recommendations when installing anti-static vinyl flooring

Here are some guidelines to ensure a smooth and high-quality installation of Vinyl flooring:

- Vinyl flooring does not have moisture-resistant properties like some other types of flooring such as wood or tile. Therefore, it is important to take preventive measures against moisture before pouring the concrete, as the surface materials can be damaged when the floor is moist, leading to additional costs, complex repairs, and inconvenience.

- Ensure that the surface is clean, dry, and smooth before installation. Remove any impurities, dust, excess concrete, and mortar from previous contractors.

- Ensure that the Vinyl tiles are installed tightly together with a maximum gap of 1.5mm.

- Ensure that the installation area is not prone to water pooling or exposure to rain.

- Monitor and implement proper maintenance measures to protect the Vinyl flooring and maintain its quality and performance.

This article is part of the DELCO exchange activities with partners, suppliers to research and apply new material solutions in the design – construction of factories, workshops in Vietnam.

The content of the article is jointly produced by DELCO Construction and G&DT Industrial Flooring Experts.

— The copyright of the article on the delco-construction.com website belongs to DELCO® Construction. Please do not copy or modify any images or content without prior written consent from DELCO®. —

See more: 6 key factors to consider to build or lease a workshop