Smart factories are an inevitable development trend of manufacturing enterprises in Vietnam, if they do not want to be left behind in the fierce competition of the market, besides the technology race of the industrial revolution 4.0 and the negative effects of the Covid-19 epidemic.

Optimal production method, increasing the competitiveness of enterprises

In the context of a highly competitive market today, with a self-screening mechanism, Vietnamese manufacturing enterprises are facing a lot of challenges, having to confront big corporations not only in the international market but also in the domestic market. How to improve production efficiency and reduce costs is not a new issue, but always requires a new solution.

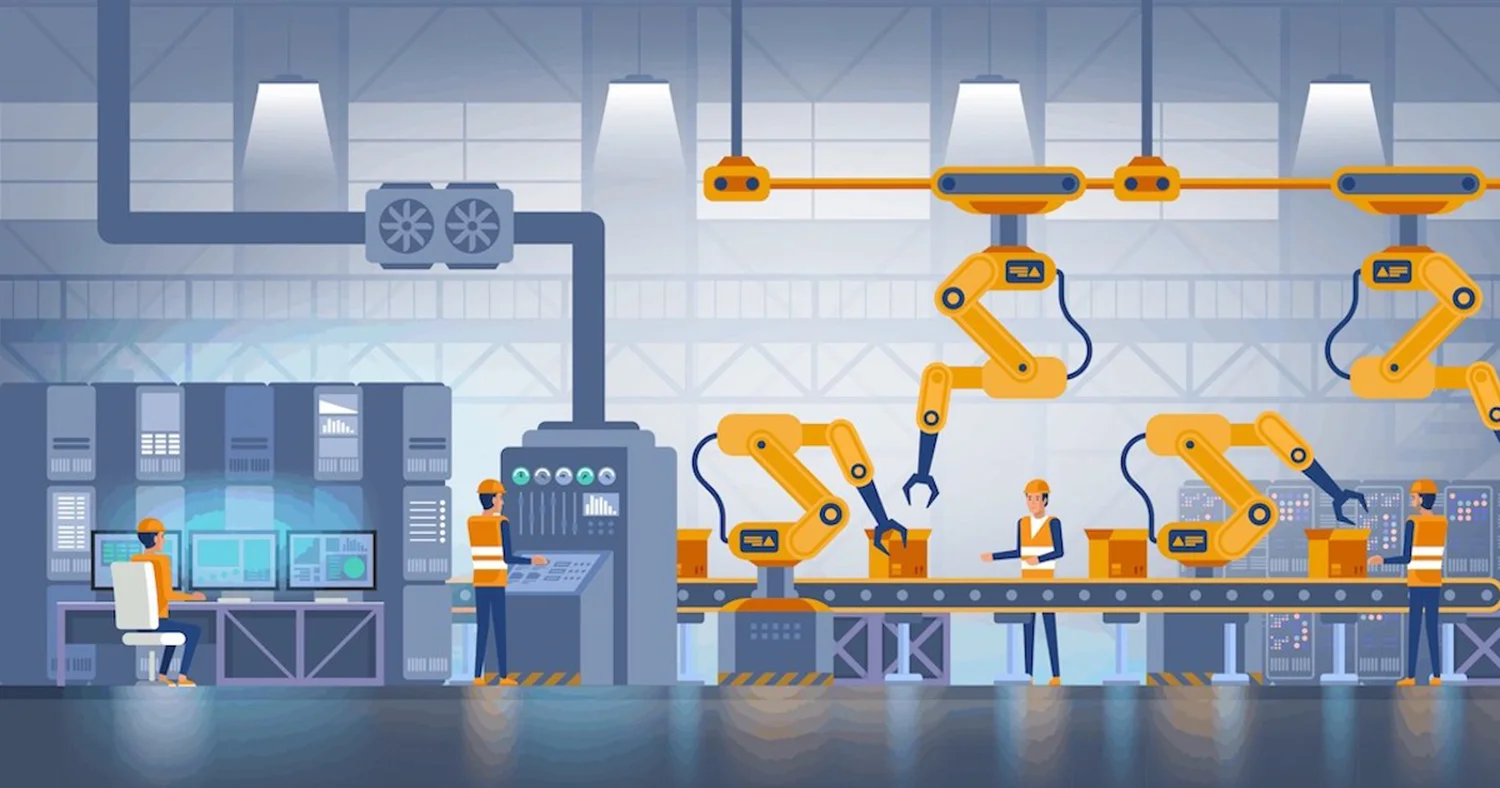

In a smart factory, automated machinery is the main resource involved in production, humans only participate in a small part of the process. Machines operate at a speed many times faster than humans, with higher accuracy, which helps to increase production productivity, reduce labor costs, and reduce the cost of defective finished products… Therefore, the Smart factory is the optimal production method that many investors choose to apply to their production plants. If businesses do not make major changes and do not apply new technologies, it is easy to fall behind in the fierce competition of the market.

The Fourth Industrial Revolution: the wave of technology

The fourth industrial revolution is based on digital technology and integrates smart technologies such as AI (Artificial Intelligence), IoT (Internet of things),… to optimize production processes. The development of technology is fundamentally changing the world’s manufacturing.

Smart factories use technologies such as AI and IoT to help increase remote monitoring capabilities, investors can control 24/24 all production activities. The entire operation of the factory is digitized, the operating parameters are measured, the system can self-analyze and adjust to suit the reality, helping to optimize the operation of machines, saving a lot of production cost.

In addition, smart factories can integrate warnings that require human intervention, warning of broken equipment, warning of expiration of warranty, maintenance, etc. Anticipating risks will help businesses proactively improvise in production, minimizing damage if production is interrupted.

The Industrial Revolution 4.0 is taking place on a global scale, which is both a challenge but also a good opportunity for Vietnamese businesses to take advantage of and deal with major problems of production industry. Smart factory solution seems as the key to opening more opportunities.

Solutions for businesses to cope with Covid-19

In the midst of the stressful situation of the Covid-19 epidemic, at businesses and factories, people are concerned about the possibility of cross – infection not only when communicating in a closed air-conditioned environment, but also when sharing public objects. The epidemic has forced the manufacturing industry to apply technology to change many processes: spacing out timekeeping, increasing the role of machines to replace human labor, managing workers and distributing resources through software, …

Read more: Attendance with Face ID technology at Power Plus Technology Vietnam Factory