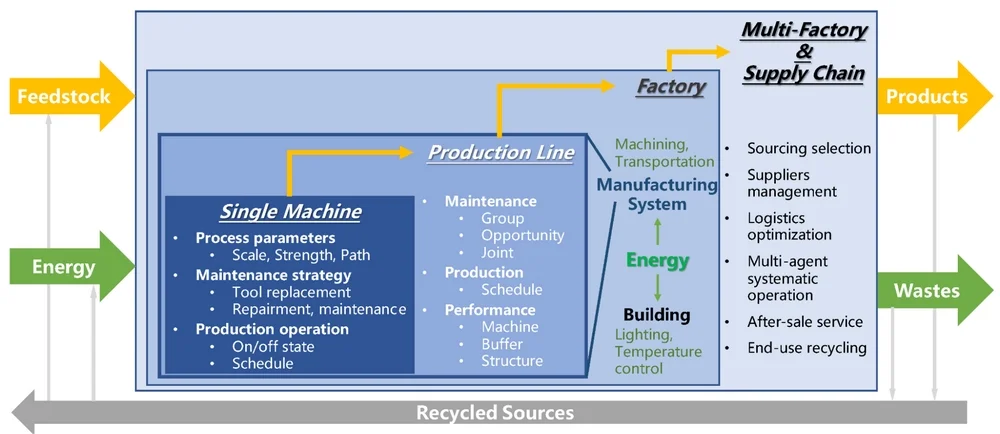

Net zero is increasingly becoming a clear direction in industrial factory development, especially for projects with high energy consumption and continuous operation. As green building standards, emission targets, and ESG criteria become part of project evaluation frameworks, MEP systems are no longer treated as separate technical packages, but as the foundation for factory-wide energy control.

In factories, achieving Net Zero is not about the form or appearance of the building, but rather how technical systems are organized in sync with actual production rhythms and operational loads. This is a key factor in minimizing energy loss and aiming for green building certifications such as LEED or BREEAM.

Net Zero is reshaping the MEP approach in factories

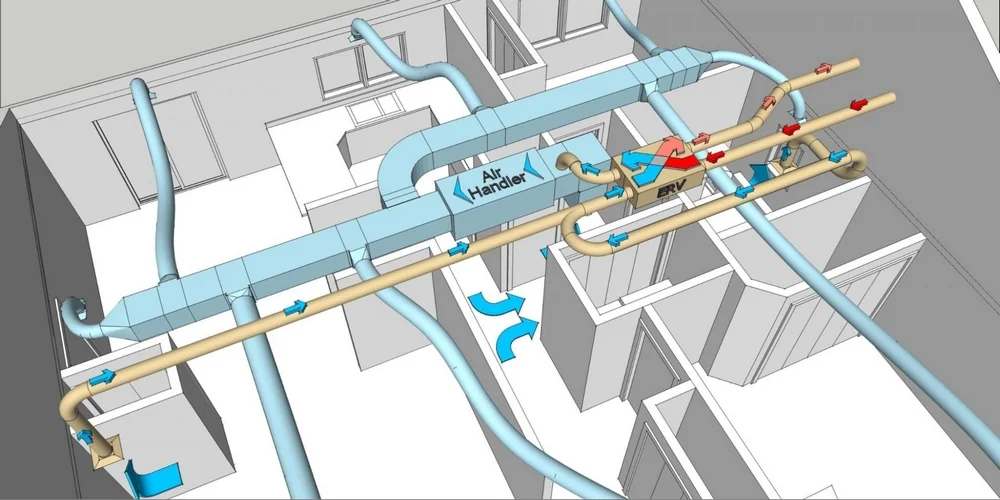

In most factories, the majority of energy consumption comes from HVAC, chillers, compressed air, ventilation, industrial water systems, and technical electrical systems. These are base loads that run continuously across production shifts, where energy efficiency depends largely on how well the systems are structured and coordinated.

Under a net zero approach, MEP is no longer a collection of separate systems. It becomes an integrated structure. Efficiency is achieved not by optimizing each system in isolation, but by enabling them to operate in sync and distribute energy based on actual demand. This is a core element of carbon reduction strategies in modern manufacturing factories.

The integration trend focuses on linking energy streams

Integrating MEP in a Net Zero factory does not mean merging all systems into a single drawing. Integration means reorganizing energy relationships between systems to avoid fragmented operation and long-term overcapacity.

A typical example is heat recovery. Heat generated during production or from chiller units only becomes efficient when it is cycled back into use rather than discharged. Similarly, compressed air is not just a supporting system—it is a significant consumer of electricity and must be managed according to load demands to avoid overproduction or long-term leakage. This is also a key element in carbon emission reduction strategies.

The boiler system at a factory where Delco serves as the M.E.P contractor has helped the investor save between fifteen to twenty-five percent in electricity consumption and significantly reduce fuel use.

In the Net Zero approach, HVAC, chillers, compressed air, and ventilation must be considered within a unified energy structure. This is the critical distinction between a factory with basic MEP investment and one that organizes MEP around emission reduction goals.

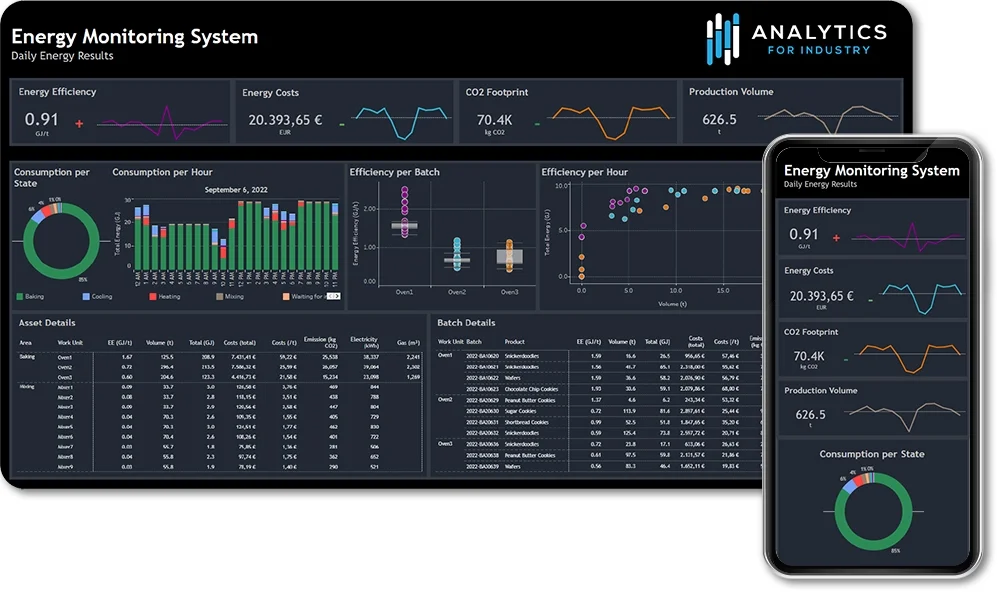

Operational data is the foundation for emission control

Industrial Net Zero cannot rely on estimations, as energy consumption varies by shift, area, and production line. Therefore, real-time monitoring and accurate separation of major load points are foundational for emission control in factories.

ESG emphasizes transparency and the ability to report operational data, rather than qualitative commitments. Green building frameworks like LEED and BREEAM also stress this data-driven aspect, as Net Zero only has meaning when its effectiveness is proven with measurable data. Without data, MEP integration remains an idea, not a long-term management tool.

Net Zero priorities always include stable production

The level of Net Zero implementation varies greatly among factories, depending on production type, operational intensity, and internal management capabilities. In practice, many factories still prioritize tried-and-tested solutions—even if they are not technologically optimized—as long as they do not compromise production stability. Energy optimization only makes sense if it does not introduce new operational risks. Therefore, the key is not to apply everything at once, but to identify the right scope of integration that fits the factory’s production characteristics and long-term management capacity.

MEP in a Net Zero factory is not a race for the newest equipment, but a transformation in how technical systems are organized—as a measurable and controllable energy structure. From being a behind-the-scenes utility, MEP is becoming the central platform that brings factories closer to emission reduction goals while maintaining operational stability. For high-energy, continuous-operation projects, adopting an integrated MEP approach—optimized according to real loads and supported by data—is not just a technological choice, but a foundational strategy.