Update industrial factory construction trends in 2024 that investors need to understand when building factories in Vietnam: multi-storey factory construction, modular construction, using green materials, beamless floor structure, etc.

Multi-storey factory construction

SSI Research forecasts that land rental prices in industrial parks in 2024 will increase by an average of 15.5% compared to 2023. Along with the limited land fund issue, many industrial parks have high occupancy rates, making it increasingly difficult for investors to find land for building factories as well as having to spend a lot of money to rent suitable industrial real estate. Therefore, multi-story factories are gradually becoming a preferred solution and a popular trend in industrial factory construction.

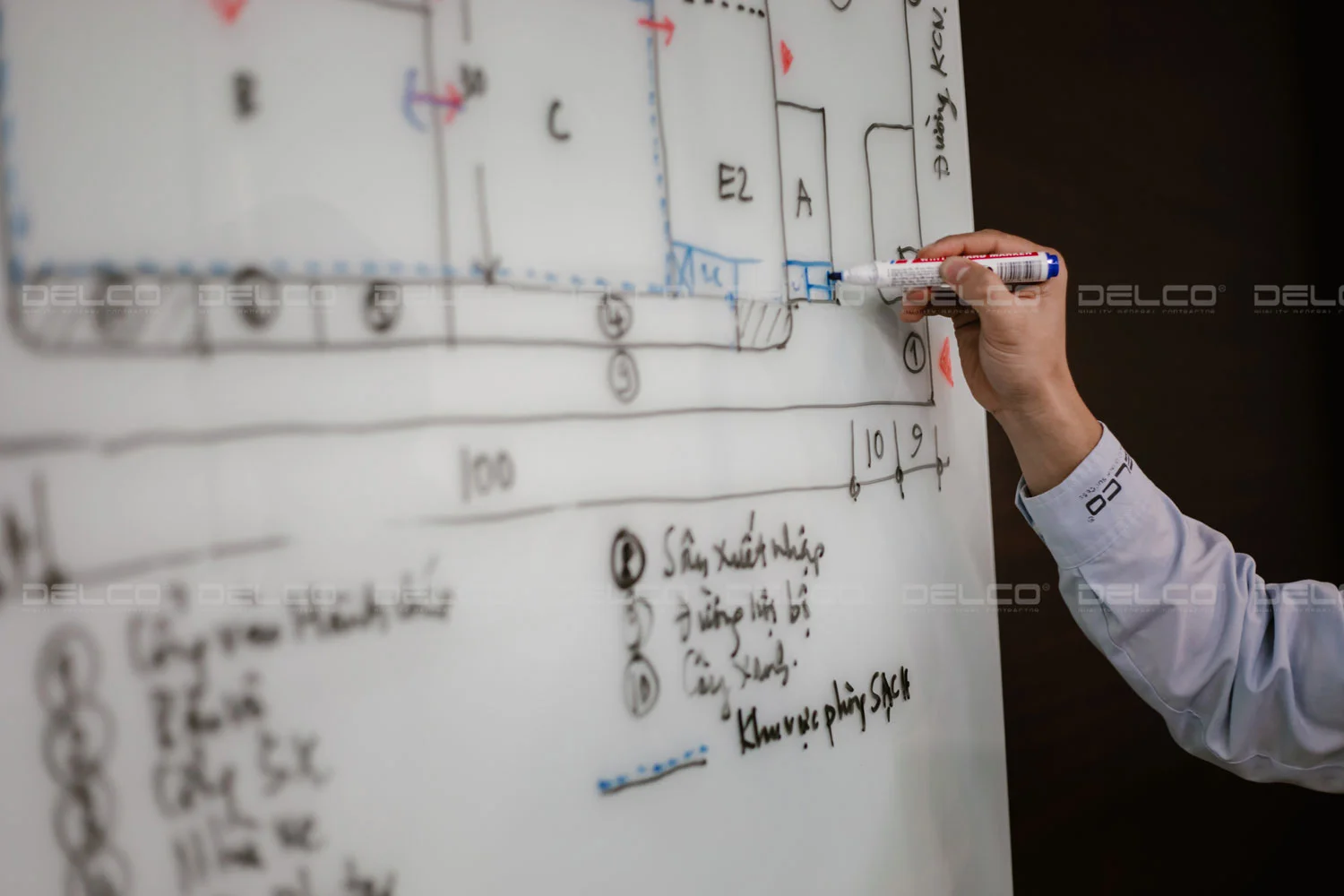

The 2-storey GS Battery Factory in Binh Duong, contracted by DELCO as the Design-Build Contractor.

Multi-storey factories offer many outstanding advantages such as optimizing factory layout and space, saving on land rental costs, and reducing transportation time within the factory. However, multi-storey workshops require sturdy foundations capable of bearing heavy loads, stable anti-vibration as well as suitable transportation methods for machinery and raw materials from the ground floor to higher levels.

Read more: Two-storey factories – the “easy but difficult” trend of industrial construction

Modular Construction – a construction time saving solution

Industrial factory construction using modular construction methods typically progresses faster than traditional construction methods. With modular construction, components such as walls, floors, and ceilings are completed off-site, then transported to the construction site and assembled on-site. This process occurs concurrently with site preparation, enabling the factory to save construction time and put into operation sooner.

Application of green and energy-saving materials

Facing the increasing risk of climate change, environmental pollution and lack of raw materials, the use of green materials in construction has become a matter of global concern and emphasis. In Vietnam, the use of green and sustainable materials in construction has become an essential trend encouraged and promoted by the government, aiming to achieve net-zero emissions by 2050.

Some common green materials used today include unfired bricks, green cement, and green concrete, etc. These are all materials produced from recycled or surplus industrial materials such as coal ash, fly ash, and are extremely environmentally friendly.

The Low E glass has the function of reducing heat absorption and dispersion, helping to save energy at the Commercial Printing Factory in Ha Nam, contracted by DELCO as the General Contractor.

Trends of factory construction using beamless floor structure

Beamless floors, designed to span large distances without the need for beams, have good load-bearing capacity, require fewer columns, allow optimization of ceiling heights. This approach is gradually becoming a popular trend in industrial factory construction. Without beams, the formwork construction will be faster, thereby speeding up the factory’s construction progress. In Vietnam, some beamless floor technologies commonly applied include prestressed floors, hollow floors, and Nevo floors, etc.

Construction of prestressed floors at the Power Plus Technology factory, contracted by DELCO as the Design-Build Contractor.

Trends of factory construction using specialized materials tailored to each industry

The development of design technology as well as new materials allows investors to choose specialized construction methods for their manufacturing industry or factory scale, meeting requirements for functionality, cost-effectiveness, and durability.

For example, in factories with narrow aisles, using robots, automation machines and forklifts to transport goods, or in some specific manufacturing factories, the use of flat floor technology and superflat floor technology becomes mandatory to ensure precise and efficient operation of equipment.

For factories in the electronics components industry where strict requirements for anti-static properties are essential, using anti-static vinyl tiles is one of the optimal solutions for businesses. Not only do these tiles possess excellent anti-static properties, but they also offer fire resistance, dust-free, easy installation and construction, and high durability and longevity.

Anti-static vinyl flooring at the HAEM VINA factory project by DELCO as the Design – Build Contractor

Read more: Prospects of attracting FDI from European enterprises into Vietnam in 2024

Read more: Factors affecting investors’ decision to rent a factory or construct a new factory