The HVAC system (Heating, Ventilation, and Air Conditioning) is a core component in creating a stable and efficient manufacturing environment in industrial facilities. However, mistakes in design and installation can lead to increased operating costs, compromised production quality, and violations of national technical standards.

1. HVAC design not aligned with the production line

In some cases, the HVAC system is designed and built separately from the factory layout, lacking integration with the production line or coordination with other essential systems like fire protection, electrical, and mechanical. This often comes from insufficient on-site surveys or when the project is divided into multiple small packages without a general technical coordinator.

As a result, repairing the HVAC system later can increase the total cost by 1.5 to 2 times after completion. Uneven temperature and airflow distribution can also affect product quality and increase maintenance costs for production equipment.

The HVAC system was installed in sync with the production line for Dainese sports protective gear factory, by Delco as the MEP Design–Build contractor.

An effective approach is to ask the contractor to carefully survey the production layout, closely coordinate with related systems, and review design drawings before construction to ensure everything is well integrated. At the same time, the HVAC system must comply with Vietnamese standards for design and installation, such as TCVN 5687:2010, and comply with fire safety regulations under QCVN 06:2022/BXD.

The HVAC system must meet design and installation standards while complying with fire safety regulations.

2. Choosing an HVAC model that doesn’t match operational needs

Selecting an HVAC system—whether VRV, Chiller, AHU, or Multi Split—that doesn’t align with the factory’s operational requirements can lead to significant issues. This often happens when decision-making focuses only on initial investment costs without considering the total cost of ownership (TCO). As a result, energy consumption may exceed projections, and operating and maintenance costs may spike. For example, a VRV system works well for office environments but is inefficient for factories running 24/7 with high heat loads. Chiller systems combined with AHUs or water-based cooling systems are often more cost-effective and perform better in continuous-use factory settings—if designed to match actual usage demands.

While a Multi Split system may reduce upfront investment and save space, it’s not ideal for facilities with constant cooling needs and high heat loads, as its performance is less stable under such conditions.

Investors should require contractors to evaluate TCO based on the factory’s operational information, while ensuring the system complies with Vietnam’s Minimum Energy Performance Standards (MEPS).

3. Failure to meet production environment control requirements

The HVAC system may not meet the requirements for temperature, humidity, pressure, or air filtration—especially in industries like electronics, food processing, or pharmaceuticals. This often happens when the system is not integrated with automatic monitoring and control systems such as BMS (Building Management System) or SCADA. As a result, defective product rates may increase, cleanroom-required operations can be disrupted, and international certifications like GMP, ISO, or HACCP may be lost—damaging the company’s credibility.

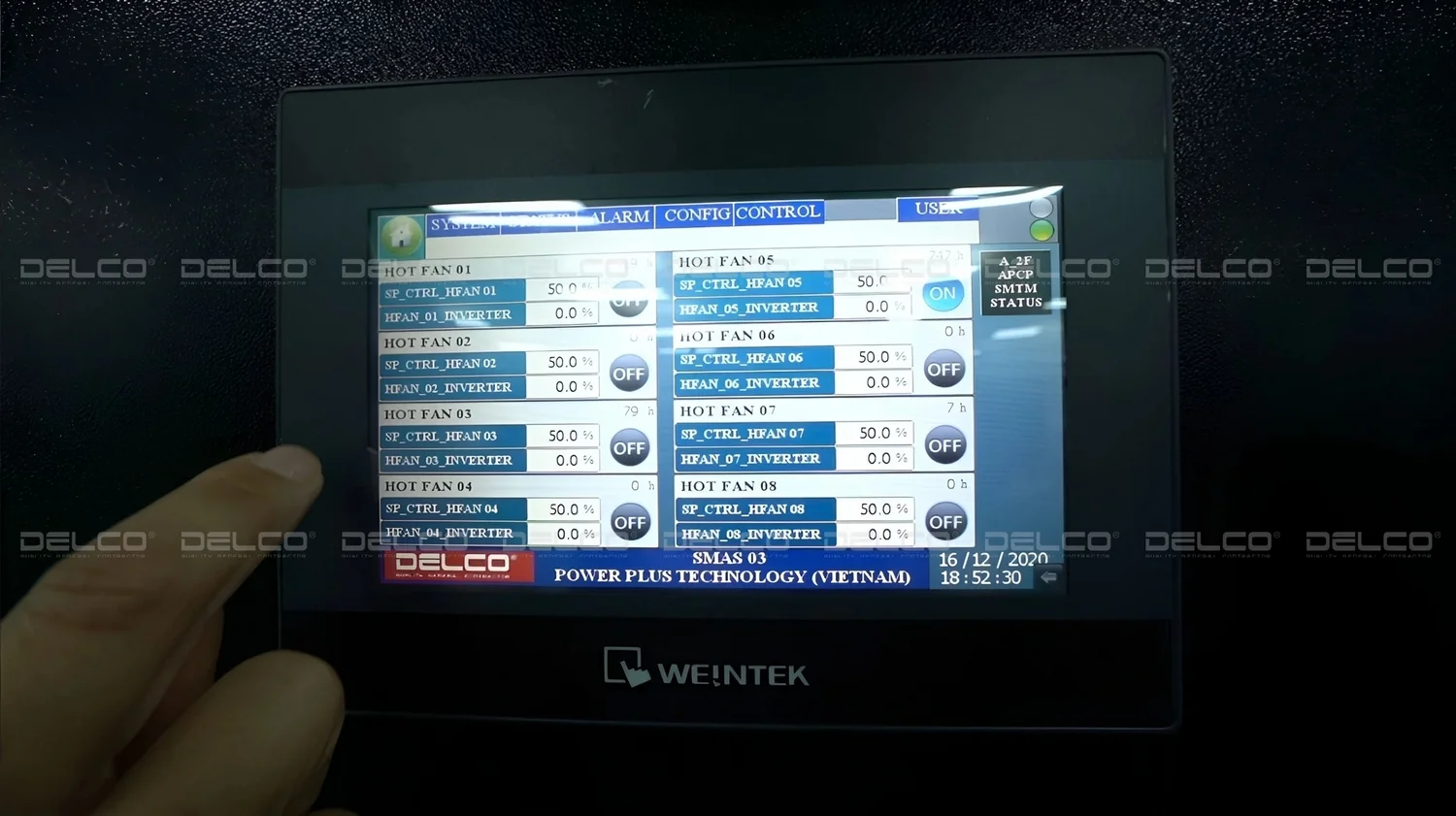

Ventilation control panel in the Power Plus Technlogy factory, by Delco as MEP Design–Build contractor.

A practical solution is to ensure the HVAC system is designed to meet industry standards and integrated with BMS/SCADA to allow automated monitoring and adjustment. In addition, a technical handover should be done before operation. The system should also meet indoor air quality requirements under TCVN 5687:2010, as well as international standards like ASHRAE or CIBSE.

4. Installation not meeting technical standards

Improper HVAC installation—such as misaligned gas or air ducts, lack of vibration or noise control, or incorrect elevation—is often caused by poor test-run procedures or missing operation records.

This can lead to early compressor failure, higher maintenance costs due to the need to dismantle the system, or even fire hazards caused by non-standard connections, violating QCVN 06:2022. If the system is tested without detailed documentation such as operation logs or measurements of electricity, temperature, and pressure, hidden faults may appear after 6 to 12 months of operation.

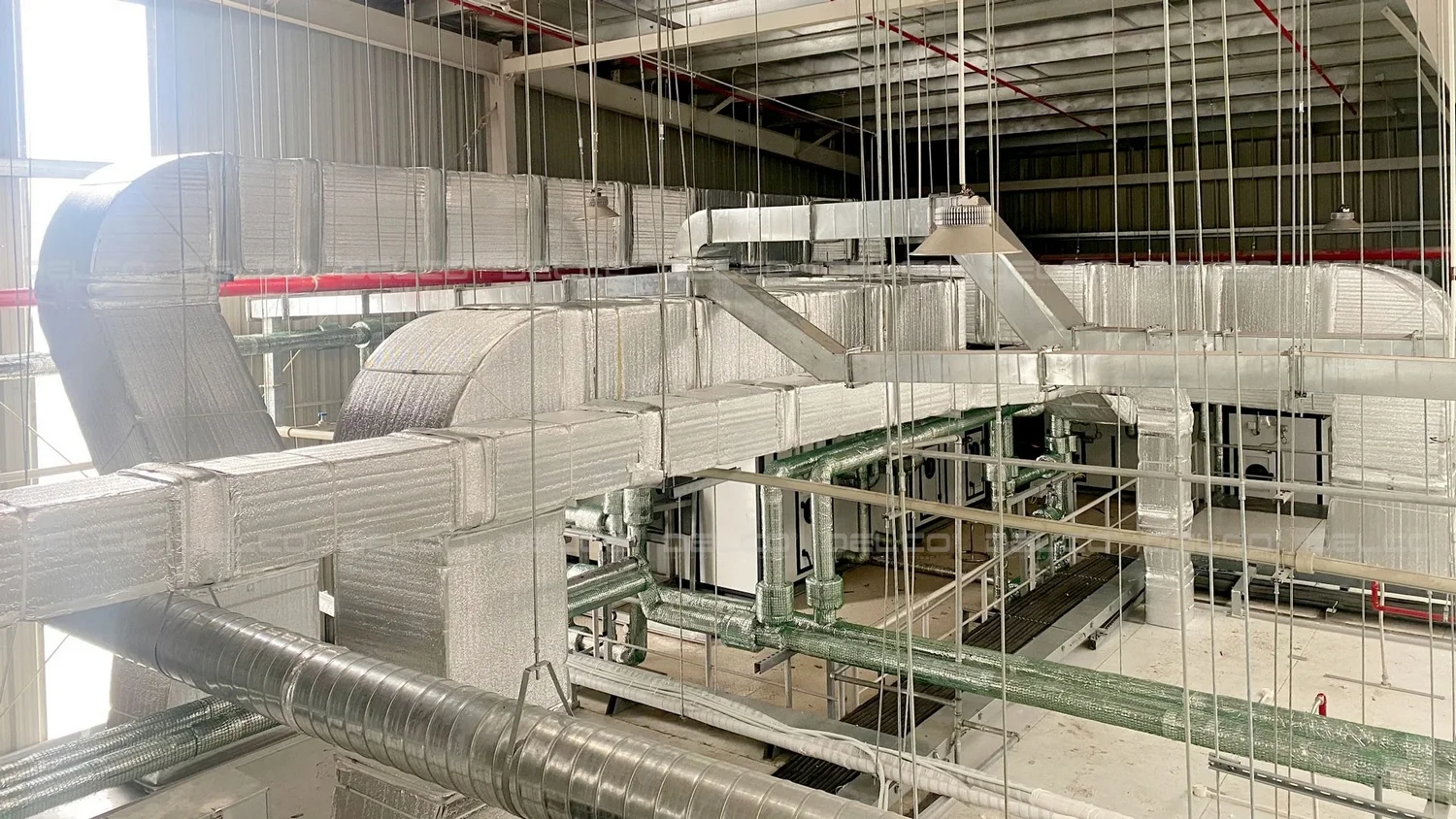

Air duct system in the HVAC system

The best way to avoid this is to require the contractor to carry out a full trial run with complete documentation, thoroughly inspect installation quality, and ensure the contract includes 100% load testing before handover.

5. Lack of a clear operation and maintenance (O&M) strategy

Not having a clear O&M plan—or relying entirely on the contractor for system operation and maintenance—is often the result of investors overlooking documentation and internal team training.

This can lead to high outsourcing costs, loss of warranty due to non-compliance with procedures, and energy waste caused by the lack of operational data. Poorly maintained systems can also disrupt production and make troubleshooting more difficult.

The HVAC system needs a clear and detailed O&M schedule to ensure long-term stable performance.

A practical way to improve this is to require the contractor to provide detailed O&M documentation, including a maintenance schedule, sensor layout, checklists, and internal training sessions to reduce dependency.

Recommendations for investors

To ensure an efficient HVAC system, investors should:

- Consider the total cost of ownership (TCO), not just the upfront equipment cost.

- Ask for a specific operation model, not vague descriptions.

- Ensure 100% load testing with detailed test and measurement reports.

- Choose a transparent partner who provides clear technical documentation and long-term support.

- Ensure compliance with regulations such as QCVN 06:2022 and national energy-saving policies.

Design and installation mistakes—such as poor integration, wrong system selection, failure to meet environmental standards, low-quality installation, or lack of an O&M strategy—can all lead to financial and operational losses. By requiring thorough site surveys, well-defined contracts, and complete O&M documentation, investors can minimize risks, ensure production efficiency, and maximize the return on investment.

See more: HVAC technology trends in Vietnam in 2025