A well-designed MEP (Mechanical, Electrical, and Plumbing) system that suits the factory’s industry and scale provides a solid foundation for stable, safe, energy-efficient operations and future expansion. This is a key success factor for FDI investors, whether they’re building new factories, leasing ready-built facilities, or renovating and upgrading projects.

1. Electrical system

The electrical system is the most critical component, supplying stable power for all production and operations. During design and installation, it’s essential to balance between safety, scalability, and investment cost.

Whether building a new factory or leasing an existing one, investors should carefully assess current power capacity and future expansion needs. This helps ensure that cable layouts, transformer locations, main switchboards, and distribution routes are aligned with the actual production lines. In execution, precision is key: systems should be clearly labeled, neatly installed, and technically compliant to ensure easy and efficient long-term maintenance.

The electrical system is clearly marked, neatly installed, and properly engineered for easy long-term maintenance.

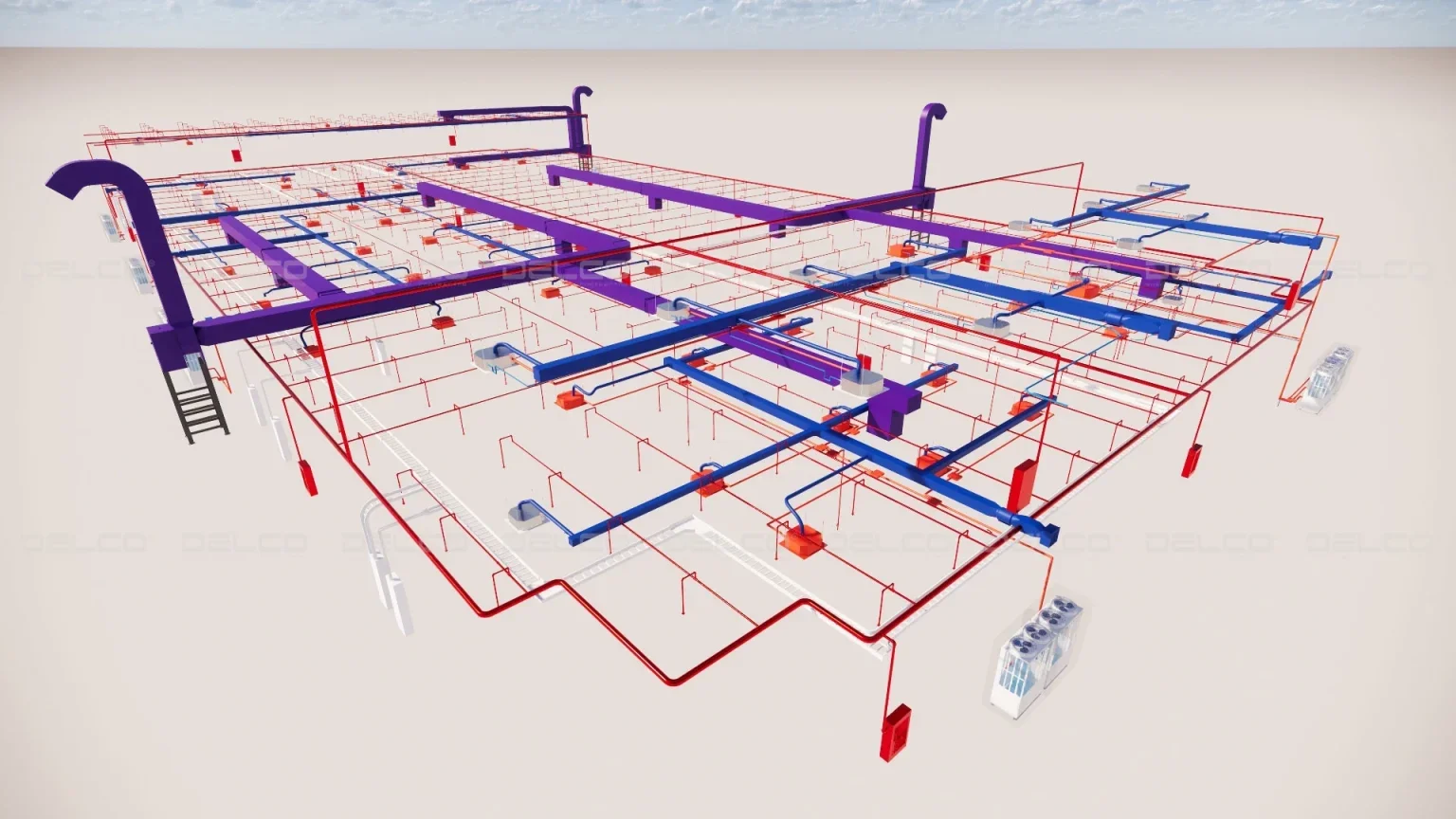

2. HVAC system

The heating, ventilation, and air conditioning (HVAC) system should be customized for each area of the factory. For high-heat workshops like metalworking or casting, it’s important to calculate proper airflow and position air outlets effectively to improve cooling performance. In controlled environments such as cleanrooms, cold storage, or food and pharmaceutical processing zones, the system must precisely maintain temperature and humidity while meeting high air filtration standards.

For office areas, the ideal setup combines energy-efficient systems like VRV/VRF central air conditioning with a smart control system (BMS). A fresh air supply with HRV should be included to ensure low CO₂ levels and clean indoor air. In addition, using natural light and ventilation where possible helps reduce the overall MEP system load.

See more: Common mistakes in HVAC design and installation for factories

3. ELV system

Extra-low voltage (ELV) is no longer just a supporting system—it has become a key part of factory digitalization. Systems such as CCTV, LAN–Wi-Fi networks, public address, and access control should be designed in sync, ensuring ease of use and simple maintenance.

In the era of smart factories, ELV should be flexibly integrated with platforms like SCADA, IoT, or MES for remote monitoring and control, helping reduce the need for on-site personnel. An open design approach also allows future upgrades and easy integration of automation modules.

At Power Plus Technology factory, a facial recognition attendance system (Face ID) has already been implemented as part of a smart ELV solution, improving internal

4. Fire protection system

Fire protection is not just a legal requirement—it’s a commitment to safeguarding people and assets in a high-risk industrial environment.

Assessment of fire protection system at Dainese factory by DELCO as MEP Design-Build Contractor

To ensure safety and operational efficiency, the fire protection system should be integrated right from the factory design stage. It must align with the facility layout, structural elements, and building materials to meet safety standards while optimizing long-term functionality.

A properly installed fire protection system must comply with standards such as QCVN 06:2022, adhere to legal regulations, and undergo regular inspections to ensure readiness in case of emergencies.

An experienced and capable contractor plays a key role in proposing tailored fire protection solutions for each industry—be it food processing, electronics, or chemicals. This helps speed up the approval and inspection process, optimize investment costs, and keep FDI projects on schedule.

See more: Important key points of fire safety regulations in factory construction

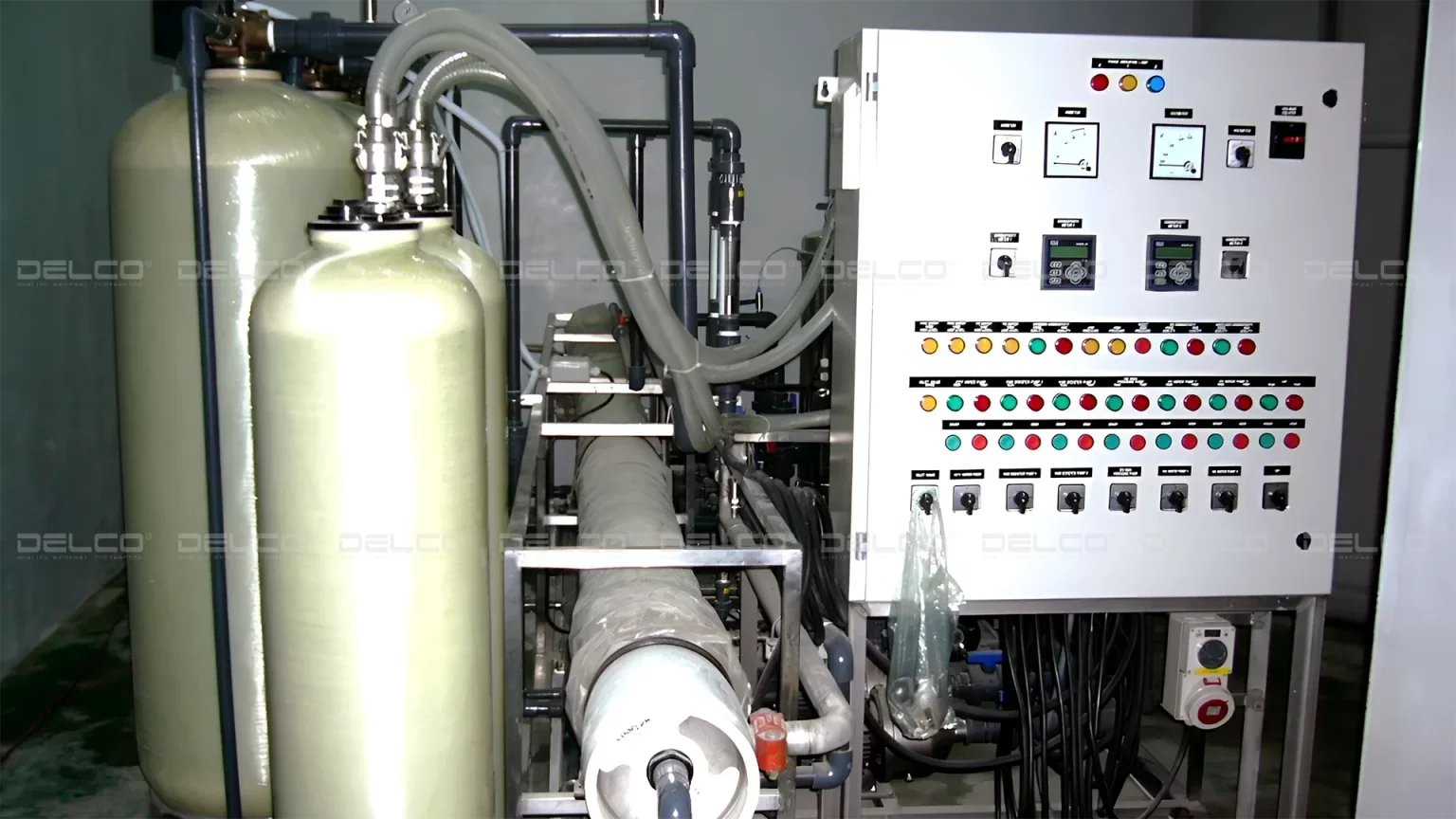

5. Water supply and wastewater treatment system

From domestic water and production water to stormwater drainage and wastewater treatment, the entire water system must be designed for optimal flow, using durable materials like HDPE, uPVC, or stainless steel 304/316 depending on the application. At the same time, it should ensure:

- Easy maintenance and allow future expansion

- Reuse of treated water to cut costs and align with global ESG trends

- Full compliance with Vietnam’s industrial discharge regulations, ready for audits by parent corporations or international organizations

Wastewater treatment system at Spindex factory, installed by Delco

A MEP contractor not only handles construction but also works closely with investors from the early planning and design stages. With extensive experience, they can propose integrated solutions that fit the specific industry, ensure long-term operations, and avoid system conflicts during construction and usage. They manage timelines closely, optimize budgets, and carry out professional construction to shorten project duration. Most importantly, they provide long-term maintenance and support—accompanying the investor throughout the factory’s lifecycle to keep the MEP systems stable, efficient, and adaptable as the factory grows.

See more: Considerations when designing and constructing the factory’s M.E.P system