As a protective cover for the entire factory, the selection of suitable covering structure and the construction with technical and quality assurance are the decisive factors for the sustainability, safety and efficiency of production activities.

What is the covering structure of the factory?

The covering structure of a factory is an important part in the structural design of the factory, which is the outer shell protecting the entire production activities and equipment lines inside the factory from the impact of the external environment such as sun, rain, wind, storm, and among others. As the outer shell, the covering structure also determines the aesthetics of the factory. In addition, the covering wall is closely linked with the column, frame and truss system, participating in load bearing as a structural component of the construction and supporting the roof system.

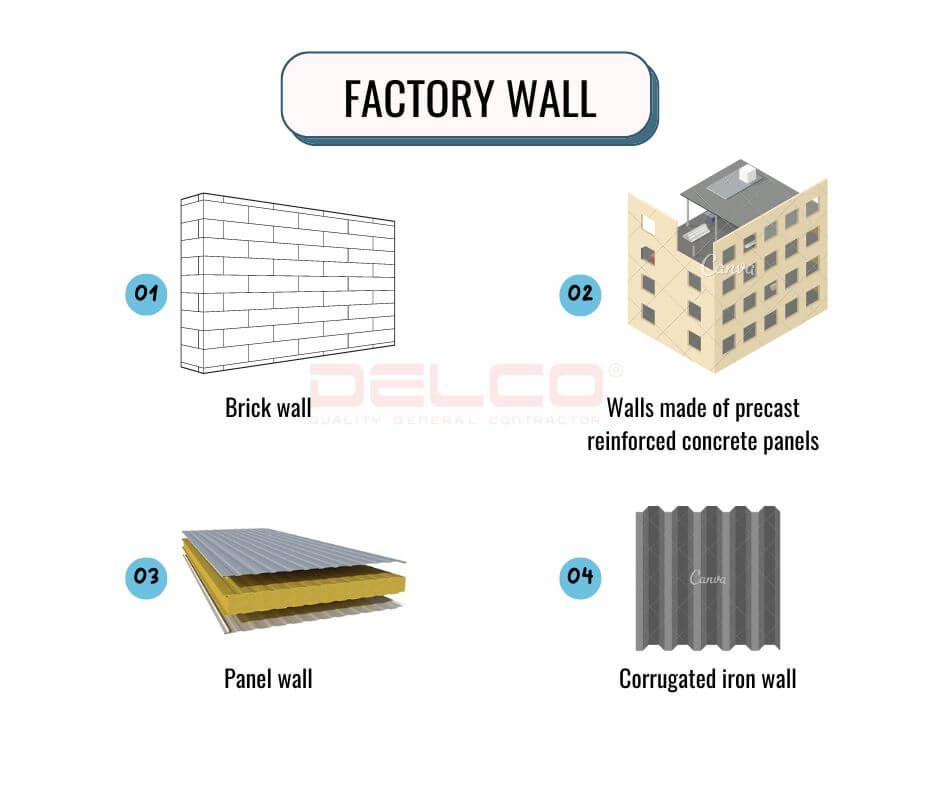

Structures covering of industrial factories include walls (brick walls, prefabricated wall panels, reinforced concrete walls, corrugated iron walls, etc.); roof (corrugated iron roof, fibro-cement roof, etc.); doors (windows, doors, roof doors); floor.

In addition to the requirements of being in accordance with the production model, adapting to the climatic and environmental conditions, the construction of the covering structure requires quite high technique and quality. The durability of the structure will directly affect the safe and efficient production activities of the factory.

Popular types of factory covering structures

Factory wall

– Brick wall:

Brick walls are a fairly common covering solution. Brick is made of inert materials; therefore, it has the ability to effectively insulate and resist fire. Walls can be built straight up over the roof when there is a drainage system by the inner roof, or the roof can be built out and drained by the outside gutter.

Construction of a brick wall covers over the roof at DORCO Living Vina Factory in Ha Nam. The wall is 10.5m high, requiring the general contractor DELCO to have complex construction methods to ensure progress and safety.

On the market today, walls made of autoclaved concrete bricks are increasingly popular because of their lightweight characteristics and unburnt manufacturing process, which do not emit too much CO2, are environmentally friendly and are in line with the recent trend of “green” factories.

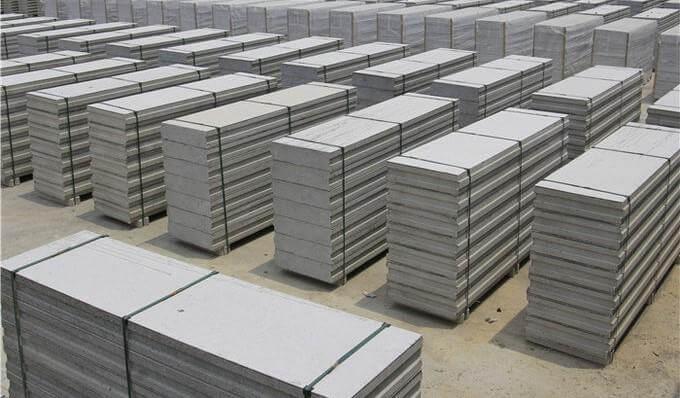

– Walls made of precast reinforced concrete panels:

Precast concrete wall panels are usually large in size, from 500mm to 1200mm wide, with a variety of thicknesses from 80 to 200mm, and use concrete grade of 200 or more. With a large size, the erection and construction will be fast and save materials, speeding up the progress.

However, precast concrete wall panels are not suitable for factory designs that require a lot of angles because the wall panels are not easy to cut and grind. Wall panels have a large size and weight; therefore, it is difficult to transport and install. Besides, the construction has very strict technical conditions, the joints between the concrete panels must be handled properly, otherwise it will be easy to crack. Precast concrete wall panels are much more expensive than traditional brick wall materials.

– Panel wall

The panel wall is made up of panels, which include two pieces of colored flat corrugated iron outside and a foam sheet in the middle. With the outstanding advantages of good bearing capacity and light weight, fire resistance, sound insulation, good heat insulation, the panel is widely applied to many different construction items such as workshops, industrial cold storage, office buildings, etc.

Curious Seiki Factory in Tien Son Industrial Park, Bac Ninh, which is implemented by the General Contractor DELCO, uses EPS panel walls with modern architecture, fast construction progress.

– Corrugated iron wall

Corrugated iron is a cheap material, has diverse colors and light weight; therefore, it reduces a lot of pressure on the foundation structure system. The corrugated iron sheets can be produced with colors and shapes at the request of investors, meeting the aesthetics and purpose of each factory. However, to ensure the durability of the steel frame factory, the stage of choosing the type of corrugated iron and the supplier is very important. It is advisable to choose a reputable manufacturer with good quality coatings to increase corrosion resistance due to weather, increase rust resistance as well as fire resistance.

GS Binh Duong Battery Factory, which is implemented by the Design-Build General Contractor DELCO, uses the covering structure of corrugated iron walls with insulation.

Factory roof

In the industrial factory structure, the roof plays an important role, ensuring the sustainability of the building. Industrial roofs need to ensure the following factors, namely good waterproofing, fast drainage, being in accordance with the technological characteristics and technical requirements of the factory.

Covered roof item can be made of reinforced concrete or light materials (roof with roofing sheets) with good bearing capacity:

– Roofs with roofing sheets using fibro-cement or corrugated iron roofs with steel trusses have the advantages such as waterproof, good leak-proof, fast construction and installation, easy maintenance – replacement, light weight and low cost. The corrugated iron roof is light in weight, so the supporting structure is also lighter and it does not need many columns inside the factory, creating flexibility for production space. However, this roof has poor insulation, poor sound insulation, and is easily affected by strong winds, hurricanes, storms that break the structural frame.

Steel truss corrugated iron roof at Power Plus Technology factory in Bac Ninh

– Reinforced concrete roof has high durability, heat resistance, good fire resistance and long service life. However, due to the poor ability to span the span of the concrete structure, many columns are needed to support the roof system, which will affect the production space in the factory. In addition, construction of concrete roofs has a high cost and the construction schedule is longer than that of roofs with roofing sheets.

Windows, doors, roof doors

The door system is arranged along the factory:

- Lighting door is a door with fixed glass frame

- Ventilation doors are shutters made of corrugated iron, steel or concrete panels.

- Mixed door for both lighting and ventilation is a type of glass door that can be opened and closed

- Doors are arranged to facilitate internal traffic in the factory, optimizing the production process.

- Roof doors are arranged on the middle spans of the factory, which has the effect of dissipating excess heat to the outside and increasing lighting for areas far from windows.

Selecting the right type of door, shape and material, designing the door position scientifically will help take advantage of natural ventilation and lighting, saving a lot of operating costs for the factory.

Aluminum and glass door systems including doors, windows and lighting doors are arranged reasonably, providing open space, sunshine and landscape in the office area of Power Plus Technology factory in Que Vo III Industrial Park, Bac Ninh which is designed and constructed by DELCO as the Design-Build General Contractor.

Factory floor

The foundation is the load-bearing part of the entire factory, the machinery system and the production activities in the factory. Therefore, in addition to the requirements of stability and durability, the floor in factories and warehouses must ensure waterproof, moisture-proof, wear-resistant by mechanical and chemical impacts during the production process, limiting dust generation, and being easy to clean.

Depending on the specific needs of each factory and the technical requirements of each manufacturing industry, it is possible to choose the right solution for the factory floor such as epoxy flooring, hardener flooring which is widely used in factories; antistatic vinyl flooring suitable for factories manufacturing electronic components; Polyurethane flooring suitable for harsh production environments such as cold storage, chemical factories, etc.

See more: Popular factory flooring solutions

— The copyright of the article on the delco-construction.com website belongs to DELCO® Construction. Please do not copy or edit any images or content without the written consent of DELCO®. —