When constructing workshops and factories in regions with harsh tropical climates, investors should consider selecting materials that have good durability and moisture resistance to reduce the impact of the environment and increase the lifespan of the building.

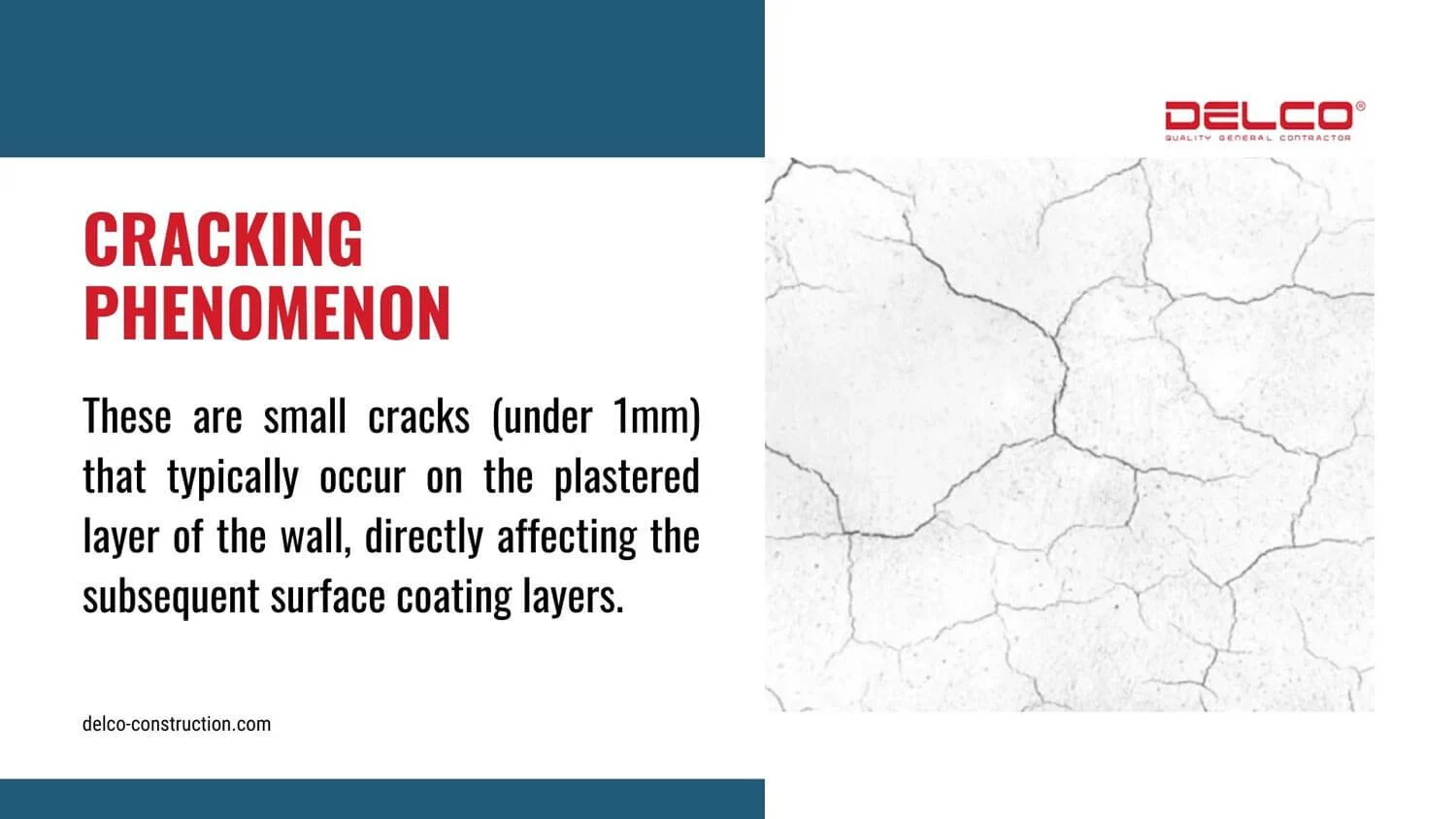

After a certain period of usage, construction often experiences issues with ≤ 1mm cracks on the surface, which negatively affect the aesthetic appearance and the lifespan of the building. Using normal paint coatings for repainting cannot completely eliminate these cracks.

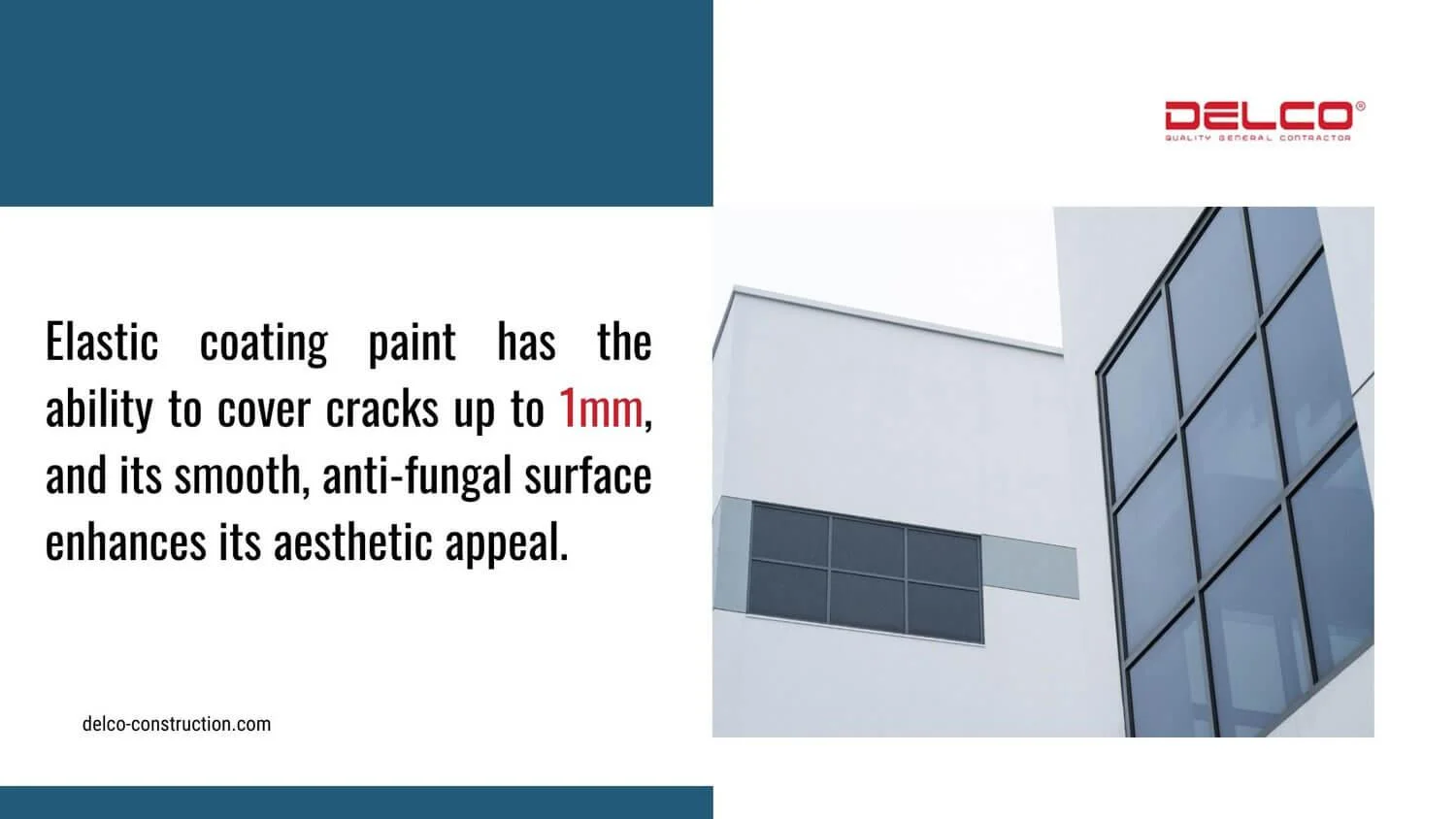

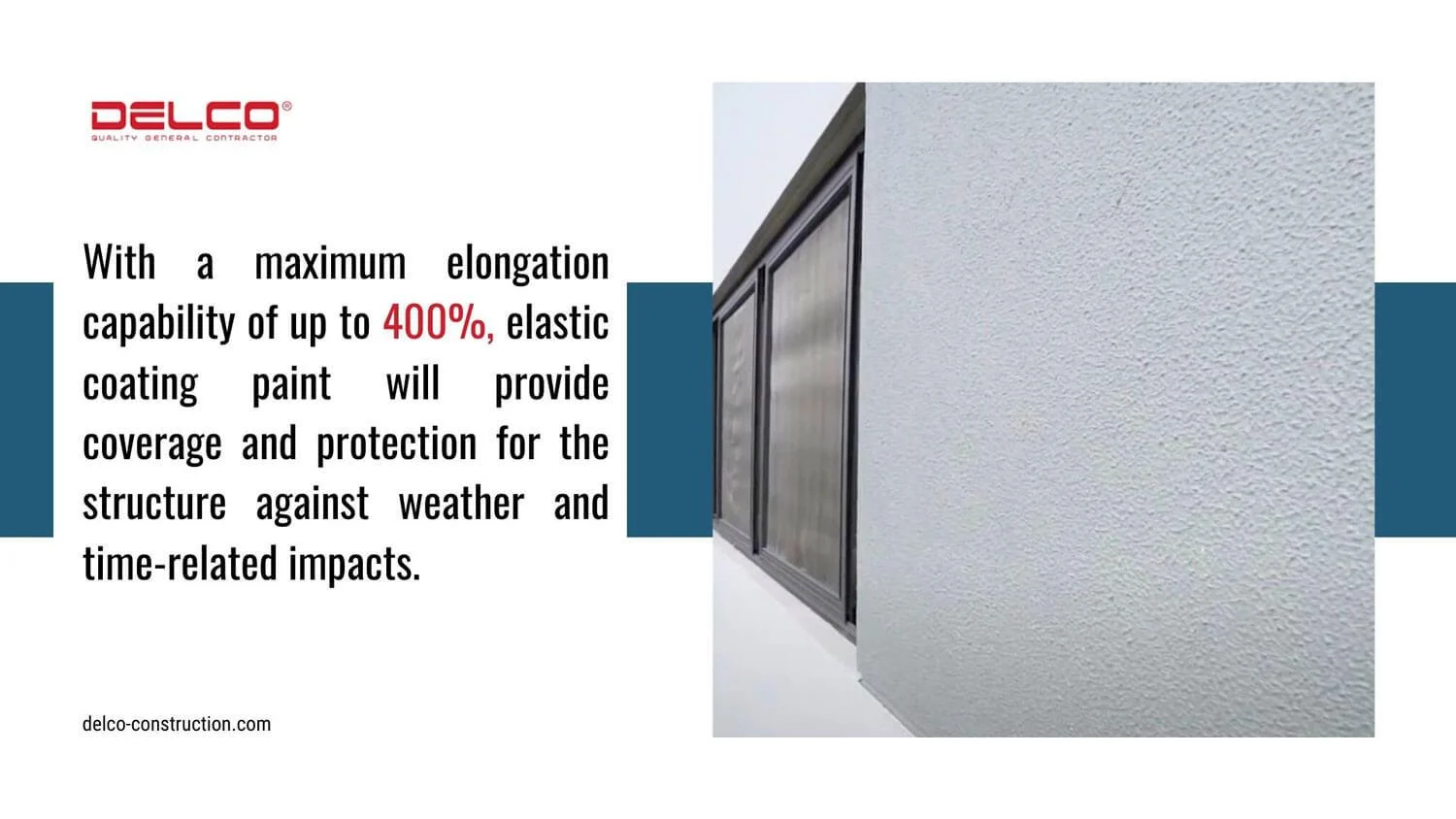

In this case, elastic coating paint is a material solution that investors should consider using to handle the ≤ 1mm cracks on the surface. This is an acrylic-based paint that has the ability to stretch and create a perfect coating layer. Elastic coating paint provides a flexible and resilient coating layer that helps to adjust surface differentials and deformations, preventing the occurrence of ≤ 1mm cracks.

Advantages of elastic coating paint

Besides its good coverage, elastic coating paint offers other advantages that help protect the construction from environmental impact, and meet the requirements for the aesthetics and durability of the construction.

- Outstanding weather resistance

- Good moisture permeability

- Resistance to fungal and moss growth

- Resistance to carbonation and the deterioration of cement

- Good washability

- High adhesion to surfaces

- Free from harmful substances such as lead and mercury

Types of factories should be applied elastic coating paint

- Important facade surfaces that require a high-durability paint coating, minimize the ≤ 1mm cracks that lead to wall degradation.

- Factories or workshops required repainting that has multiple cracks on the surface ≤ 1mm

- Factories or workshops located in tropical climates with significant temperature differentials between day and night.

Elastic coating paint is applied in the construction of commercial printing factory DORCO LIVING VINA – DELCO design-build contractor

Recommendations during construction

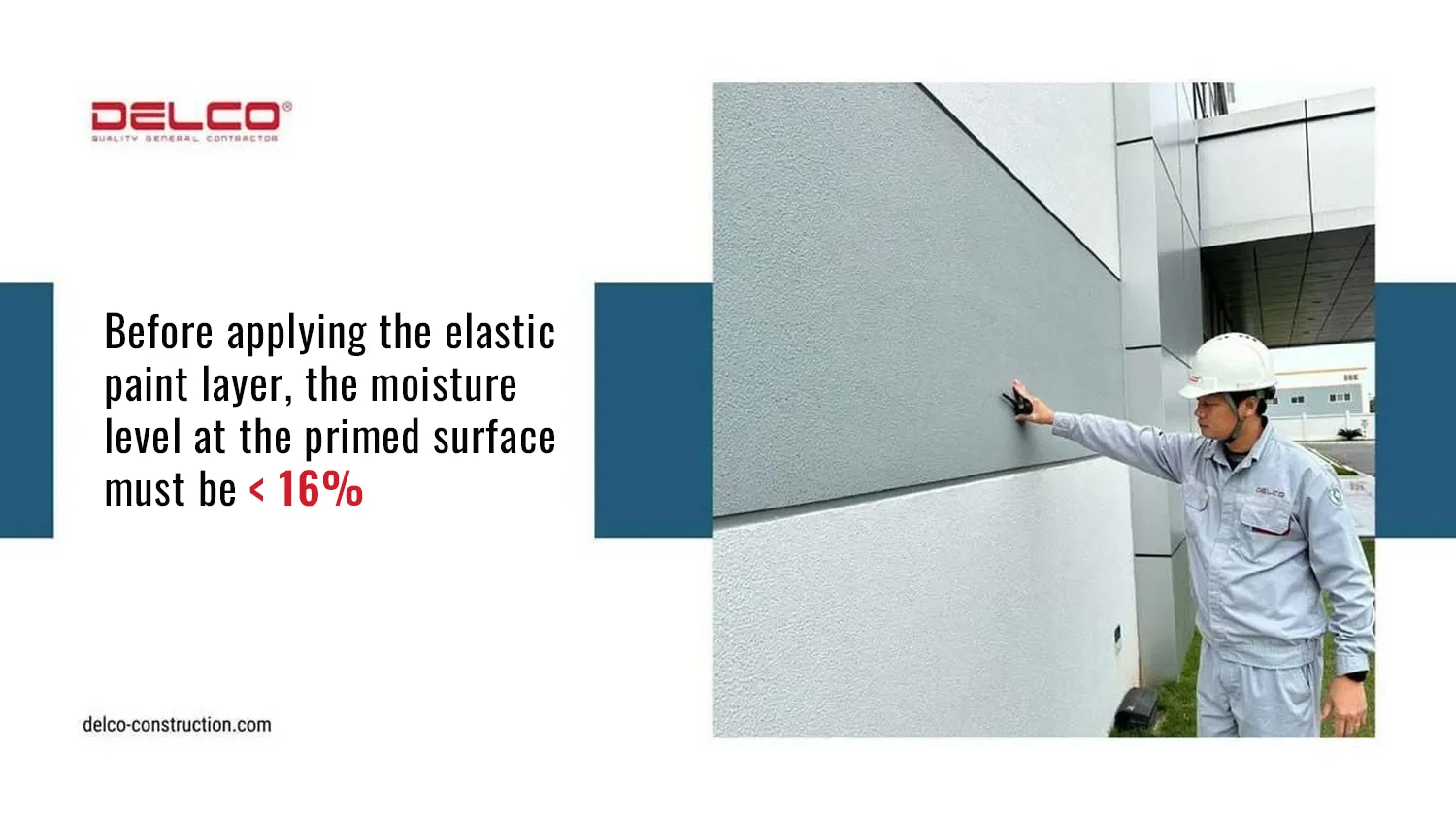

When applying elastic coating paint in construction, there are some important considerations to be followed to ensure maximum elasticity and aesthetic quality of the paint. Here are some key points must be considered during the construction of elastic coating paint:

- Strictly control the moisture level before painting, with moisture content at the time of primer application ≤ 16%.

- The plastered surface should be allowed to dry for a minimum of 28 days before painting, and sources of moisture infiltration must be thoroughly addressed before applying the elastic coating paint.

- Elastic coating paint is suitable for covering cracks ≤ 1mm. For larger cracks, it is necessary to fill and treat them before proceeding with the paint application.

- Limit the use of putty (matit) to create a smooth surface before applying elastic coating paint. Because the elastic coating paint film is thicker and heavier than normal paint, the putty may lead to poor adhesion between the paint film and the wall surface, affecting the quality of the elastic coating paint.

- In the case of applying two layers of elastic coating paint, allow a minimum of 2-3 hours between each layer.

This article is part of the DELCO exchange activities with partners, suppliers to research and apply new material solutions in the design – construction of factories, workshops in Vietnam.

The content of the article was jointly developed by DELCO Construction and KANSAI Paint .

— The copyright of the article on the delco-construction.com website belongs to DELCO® Construction. Please do not copy or modify any images or content without prior written consent from DELCO®.

See more: Types of popular covering structures for factories

See more: Popular industrial flooring solutions