DELCO had the opportunity to cooperate with the investor DOOSAN – a South Korean multinational corporation which ranked as one of the world’s largest heavy equipment manufacturer, in the Mechanical and Electrical (MEP) project at the DOOSAN Electro-Materials workshop in Dai An Industrial Park, Hai Duong.

MEP project of DOOSAN Electro-Materials Vietnam factory

In November 2022, DELCO is honored to be chosen as the MEP contractor for the renovation project of the DOOSAN Electro-Materials factory in Dai An Industrial Park, Hai Duong. DELCO is responsible for implementing the technical systems for the production line, including the tin plating line, RSTR, QUICK PRESS , and technical pipe trench systems.

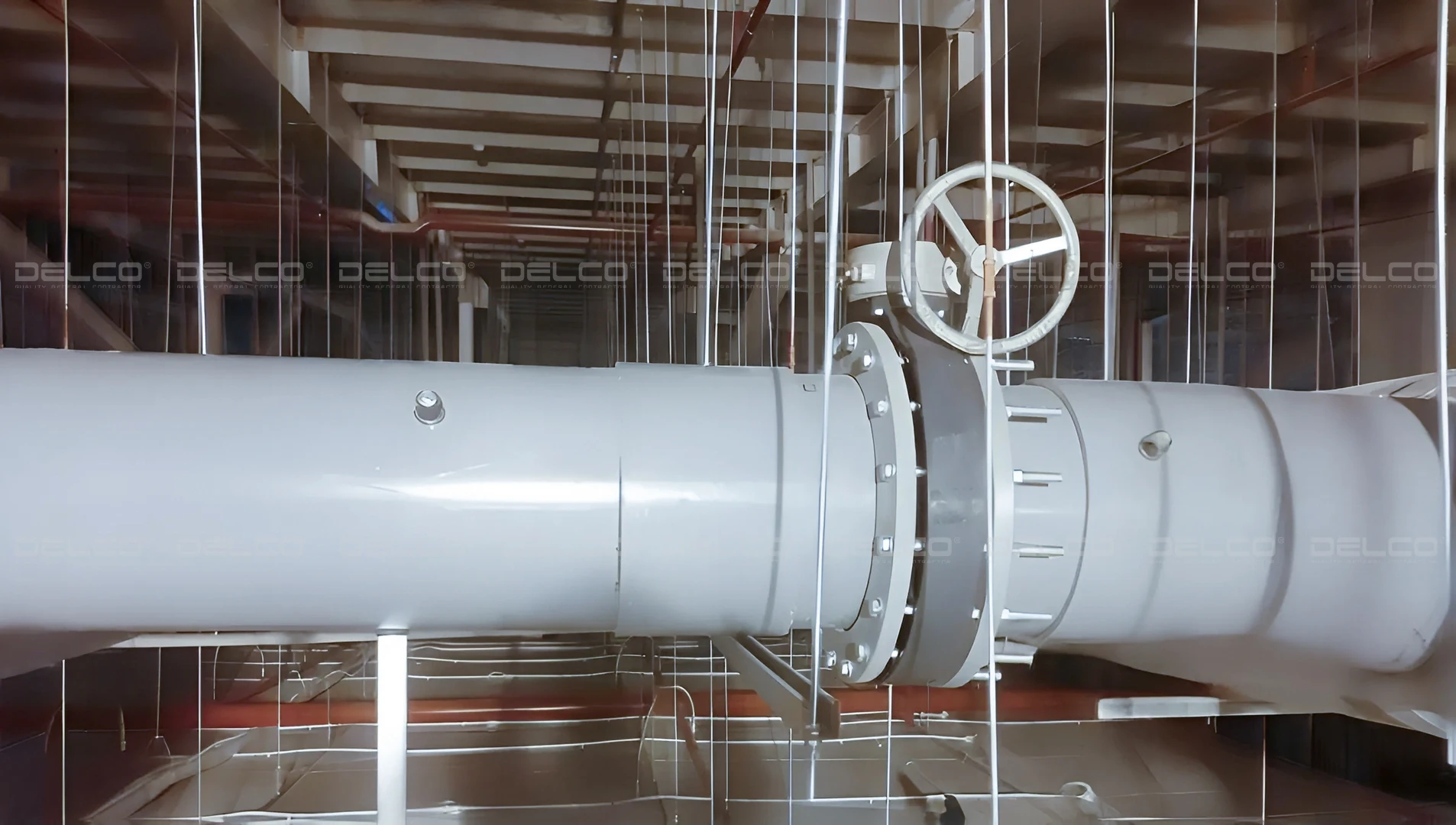

The system of welding air intake and exhaust pipe for the production line are the factory’s largest MEP pipeline systems, with a thickness up to 9.8mm.

Construction of RO & DI pipeline system

Measuring the wind speed and flow of the exhaust system at the factory

Connecting compressed air pipes for machinery lines.

Chiller pipeline system of the factory

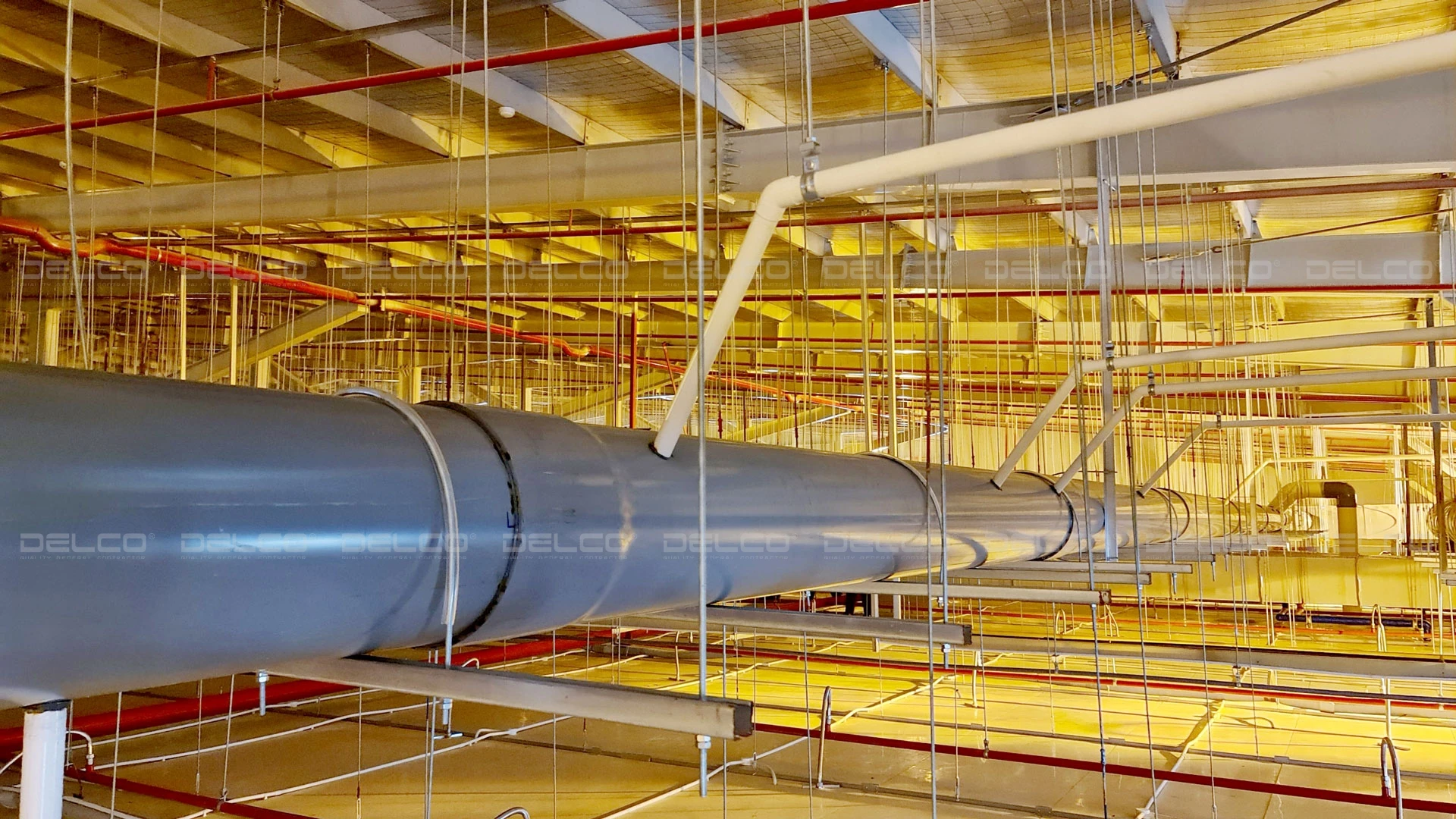

Ventilation system on the ceiling of the factory.

UPVC wastewater pipeline system is installed in the technical pipe trench with a sensor warning when wastewater leaks.

These are all important systems, requiring very high accuracy, to ensure that the factory’s machinery, equipment, and production lines can operate efficiently.

DELCO’s Construction process

The project involves the construction and renovation work while the factory maintains normal production activities. Therefore, the construction progress was very urgent within only 2 months, with narrow construction areas and spaces.

DELCO carefully implemented shielding measures to minimize dust and other impacts that may affect the production activities of the factory.

The factory’s pipelines have high requirements for technical specifications, especially the pipe thickness, high durability, large size, and strict construction standards that require high accuracy. In addition, the construction space on the completed panel ceiling is very narrow. Many complex MEP pipe systems are on the ceiling, making the construction work more difficult and requiring technical expertise and excellent organization and management skills.

The 400mm diameter tin plating line exhaust system is interlaced with a hanging threaded rod system and many other MEP pipeline systems.

The investor is particularly concerned about occupational health and safety , safety production and firefighting safety, and every item must be registered and approved by the investor before implementation . DELCO’s QC team strictly monitored and ensured the highest safety standards throughout the project. The MEP pipeline system on the ceiling is constructed and installed very carefully, paying special attention to the issues of electromechanical safety, precision and high aesthetics of each item.

About DOOSAN Electro-Materials

Doosan Electro-Materials (DSEM) is one of the business groups in Doosan Corporation, a famous multi-industry corporation in Korea. Founded in 1974, DOOSAN Electro-Materials is constantly researching and upgrading its products and technology, becoming a global top-tier company with annual revenue of USD 800 million. DOOSAN Electro-Materials currently has 3 factories in Korea, 1 in Singapore, 1 in China, 1 in Vietnam, and many branches in USA, Europe, Japan, Singapore…

DOOSAN Electro-Materials Vietnam was established in 2020, focusing on manufacturing wires, cables, circuit boards… for domestic and foreign markets.

DELCO has completed the MEP project of DOOSAN Electro-Materials factory in Dai An Industrial Park – Hai Duong on schedule, handed over and put into operation from December 2022, ensuring all requirements on occupational hygiene, occupational safety and fire prevention.